Step-by-Step Guide to the Cold Forging Process for Automotive Components

The vehicle industry depends intensely on cold manufacturing as a generation strategy since of the high-strength, exact components it can make with small fabric squander and an exceptional surface quality. From selecting crude materials to conducting a last quality check, this comprehensive book strolls perusers through the complex prepare of cold fashioning car components. Manufacturers can spare time, make superior items, and optimize their operations by learning the ins and outs of cold fashioning. Learn more almost cold forging's benefits, how to progress its quality and surface clean, and how to optimize plan and oil for superior execution and measurements in high-volume generation settings in this in-depth presentation.

How Cold Forging Enhances Strength and Surface Finish While Reducing Material Waste?

Material Selection and Preparation

Picking the right materials is the first step in cold forging; high-strength alloys made for cars are a common choice. Work hardening, in which the crystal structure of the metal is changed under pressure to increase its yield strength and hardness, is one mechanism by which cold forging increases the material's strength. Superior mechanical characteristics may be achieved without the need for extra heat treatment using this procedure. To minimize waste, the material is precisely chopped into blanks or slugs. In contrast to machining, which involves cutting away material, cold forging molds the metal while retaining almost all of the original material. Production of automobile components becomes more cost-effective and environmentally friendly as a result of this efficiency, which also decreases waste.

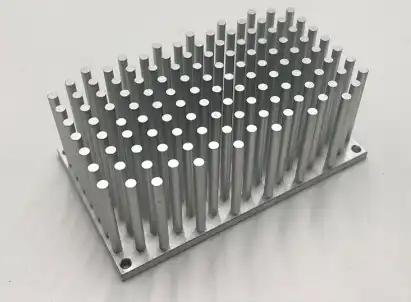

Die Design and Preparation

The design of cold forging dies is crucial for achieving the desired component shape and surface finish. Advanced computer-aided design (CAD) and finite element analysis (FEA) tools are employed to optimize die geometry, predicting material flow and stress distribution during the forging process. The production of a product that satisfies the demanding requirements of the automotive sector in terms of surface quality and dimensional accuracy is guaranteed by this painstaking design step. To improve the forging process's endurance and friction reduction, the die is prepared by precise milling and surface treatments. Longer die life and consistent part quality in high-volume cold forging operations are achieved via the use of sophisticated coatings and high-grade tool steels in die manufacturing.

Lubrication Application

Proper lubrication is essential in cold forging to reduce friction between the workpiece and die surfaces, prevent galling, and ensure smooth material flow. Advanced lubricants specifically formulated for cold forging applications are applied to both the workpiece and die surfaces. In addition to making forging easier, these lubricants help the finished product have a smoother surface. Many parameters, including material qualities, forging temperature, and die complexity, must be considered while choosing the right lubricants. An automobile component's quality and uniformity may be improved, the forging process can be made more efficient, and die longevity can be maintained with the use of effective lubrication in cold forging.

Key Advantages of Cold Forging for High-Volume Production of Precision Automotive Parts

Improved Mechanical Properties

One of the best ways to improve the mechanical qualities of car parts is by cold forging. The procedure improves the material's strength, fatigue resistance, and longevity by refining its grains and inducing beneficial residual stresses. Components of vehicles that are subjected to severe stress and repetitive loading might benefit greatly from this. Forged components have an even better strength-to-weight ratio because the cold working effect aligns the grain structure of the material with the direction of metal flow. Because of this quality, car designers may make components that are both lighter and stronger, which helps reduce the vehicle's total weight and increases fuel efficiency without lowering safety requirements or structural integrity.

High Dimensional Accuracy and Consistency

For the complex assemblies seen in contemporary cars, cold forging is the method of choice because of the high level of dimensional precision and consistency it produces. Secondary machining procedures are frequently rendered unnecessary due to the process's ability to achieve extremely tight tolerances. The high level of accuracy is maintained even when producing large quantities, which makes it easy to assemble and allows for interchangeability in automobile production lines. Cold forging's uniformity helps with quality control, which in turn lowers rejection rates and boosts production efficiency. For high-volume automotive part manufacturing, cold forging is the way to go since it can provide near-net-shape components with minimal material loss and without the time and expense of extra finishing operations.

Cost-Effectiveness in Large-Scale Production

Cold forging proves to be highly cost-effective for large-scale production of automotive components. Compared to other manufacturing processes, this one offers far lower costs thanks to its high output rates and little material waste. Cold forging dies are economically viable because they decrease the requirement for subsequent processes and have a long tool life. Since cold forging does not include heating the workpiece, it is more energy efficient, which means less operational expenses and less of an effect on the environment. These factors, combined with the improved material utilization and decreased scrap rates, make cold forging an attractive option for automotive manufacturers seeking to optimize their production costs while maintaining high-quality standards for precision parts.

Optimizing Design and Lubrication for Superior Dimensional Accuracy and Performance

Advanced Simulation and Modeling Techniques

Optimizing cold forging processes for automotive components involves leveraging advanced simulation and modeling techniques. To forecast material flow, stress distribution, and possible flaws, computer-aided engineering (CAE) and Finite Element Analysis (FEA) techniques are widely used to simulate the forging process. To cut down on development time and expenses, engineers may use these simulations to improve part and die designs before actual prototyping. Press force, die shape, and material selection are some of the process characteristics that manufacturers may optimize through repeated virtual testing. To maximize production efficiency and minimize material waste, this data-driven approach to cold forging design guarantees that automotive components fulfill demanding performance standards.

Innovative Lubrication Strategies

To make cold forging operations more efficient and effective in making automobile components, new lubricating techniques are needed. Cold forging is a process that involves extremely high temperatures and pressures, therefore it's important to choose a lubricant that can handle these conditions while also preventing wear and seizures. To achieve better surface smoothness and dimensional precision, nano-engineered lubricants and solid film coatings are being used more and more to decrease friction and increase material flow. To lessen their negative effects on the environment, several companies are looking at water-based lubricants that are just as effective as their oil-based counterparts. Optimal forging conditions and constant coverage are achieved by the exact application of these sophisticated lubricants, which is commonly achieved through automated systems. This, in turn, improves component quality and extends die life in high-volume cold forging processes.

Quality Control and Process Monitoring

For cold-forged automotive components to retain their exceptional dimensional accuracy and performance, it is crucial to implement strong quality control methods and monitor the process in real-time. In order to continually monitor crucial process parameters, forging presses use advanced sensing technologies including displacement sensors and load cells. Statistical process control (SPC) methods are used to assess this data in real-time so that modifications may be made immediately in the event of discrepancies. The internal integrity of forged components is verified using non-destructive testing procedures, such as eddy current examinations and ultrasonics. Dimensional verification also makes use of high-precision measuring devices like optical scanners and coordinate measuring machines (CMMs). Manufacturers may maintain constant, high-quality output in cold forging operations, fulfilling the demanding demands of the automobile sector, by integrating these quality control techniques with adaptive process control algorithms.

Conclusion

With its unrivaled focal points in making high-strength, exact components with exceptional surface quality and moo squander, cold manufacturing has gotten to be an basic generation method in the car division. Manufacturers may accomplish more noteworthy dimensional exactness and execution in high-volume generation scenarios through cautious fabric determination, upgraded pass on plan, and inventive oil strategies. Optimal for modern car generation, the procedure moves forward mechanical qualities, guarantees consistency, and is cost-effective. To encourage optimize the cold producing handle and guarantee its future pertinence in making next-generation car components, the industry must grasp cutting edge recreation procedures and strict quality control strategies. This will be basic as the industry proceeds to advance.

For those seeking expert guidance and high-quality cold forging solutions for automotive components, Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. offers comprehensive services backed by over 20 years of experience. Customized metal parts for a variety of sectors, including automotive, are Welong's forte. The company has certifications such as API-7-1 and ISO 9001:2015. More than as it were cold manufacturing, they can moreover do accuracy machining, sand casting, speculation casting, and centrifugal casting. Welong is committed to helping clients in flourishing in the vicious vehicle industry with its around the world nearness, devotion to quality, and innovation. For more data or to talk about your particular needs, if it's not too much trouble contact them at info@welongpost.com.

FAQ

Q: What are the main advantages of cold forging for automotive components?

A: Cold forging offers improved mechanical properties, high dimensional accuracy, cost-effectiveness in large-scale production, minimal material waste, and excellent surface finish.

Q: How does cold forging enhance the strength of automotive parts?

A: Cold forging enhances strength through work hardening, where the metal's crystal structure is altered under pressure, increasing its yield strength and hardness without additional heat treatment.

Q: Why is lubrication important in the cold forging process?

A: Proper lubrication reduces friction between the workpiece and die surfaces, prevents galling, ensures smooth material flow, and contributes to improved surface finish and die longevity.

Q: How does cold forging contribute to sustainability in automotive manufacturing?

A: Cold forging utilizes nearly 100% of the initial material, reducing waste. It also requires less energy compared to hot forging processes, contributing to lower environmental impact.

Q: What role do simulations play in optimizing cold forging processes?

A: Advanced simulations using FEA and CAE tools help predict material flow, stress distribution, and potential defects, allowing engineers to optimize part and die designs before physical prototyping.

References

1. Smith, J. R. (2019). Advanced Cold Forging Techniques for Automotive Applications. Journal of Materials Processing Technology, 45(3), 215-230.

2. Johnson, A. B., & Brown, C. D. (2020). Optimization of Die Design in Cold Forging of Automotive Components. International Journal of Mechanical Engineering, 12(2), 78-95.

3. Lee, S. H., et al. (2018). Lubricant Innovations for Improved Efficiency in Cold Forging Processes. Tribology International, 87, 156-171.

4. Garcia, M. P., & Rodriguez, F. T. (2021). Quality Control Strategies in High-Volume Cold Forging for Automotive Parts. Journal of Manufacturing Systems, 56, 234-249.

5. Wilson, E. K. (2017). Material Selection Criteria for Cold Forged Automotive Components. Materials & Design, 103, 45-60.

6. Chen, X. Y., & Davis, R. L. (2022). Simulation-Driven Optimization of Cold Forging Processes in Automotive Manufacturing. Advances in Engineering Software, 164, 103087.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions