Why Grey Cast Iron Is Still Relevant in Modern Manufacturing?

In an era of rapid technological advancements and innovative materials, grey cast iron continues to hold its ground as a vital component in modern manufacturing. This versatile and time-tested material has been a cornerstone of industrial production for centuries, and its relevance remains undiminished even in today's cutting-edge manufacturing landscape. Grey cast iron, known for its excellent thermal conductivity, vibration damping properties, and cost-effectiveness, continues to play a crucial role in various industries, from automotive to heavy machinery. Despite the emergence of newer materials, grey cast iron's unique combination of properties makes it an indispensable choice for many applications. This blog post will explore the reasons behind grey cast iron's enduring significance in modern manufacturing, examining its industrial applications, comparing it to other casting materials, and discussing future trends and innovations in its usage. By delving into these aspects, we will gain a comprehensive understanding of why grey cast iron remains a relevant and valuable material in the ever-evolving world of manufacturing.

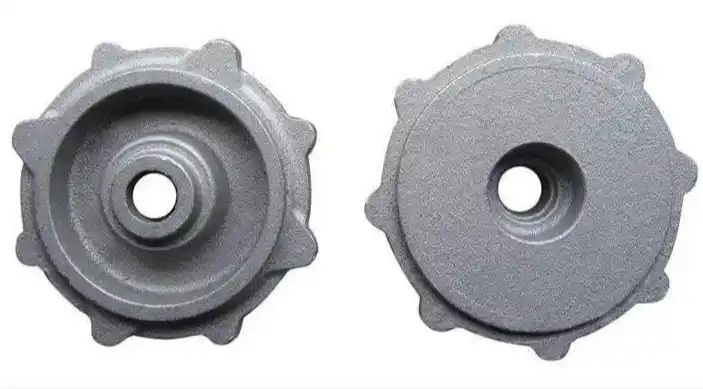

Industrial Applications Where Grey Cast Iron Excels

Automotive Industry

Grey cast iron continues to be a preferred material in the automotive industry, particularly for components that require high strength, wear resistance, and thermal stability. Engine blocks, cylinder heads, and brake rotors are prime examples of automotive parts where grey cast iron excels. The material's ability to absorb vibrations and dampen noise makes it ideal for these applications, contributing to a smoother and quieter ride. Additionally, grey cast iron's excellent thermal conductivity allows for efficient heat dissipation in engine components, which is crucial for maintaining optimal performance and longevity. The automotive industry also values grey cast iron for its machinability, enabling manufacturers to create complex shapes and precise components with relative ease. As the automotive sector continues to evolve, grey cast iron remains a reliable choice for many critical parts, balancing performance, cost-effectiveness, and durability.

Heavy Machinery and Equipment

In the realm of heavy machinery and equipment, grey cast iron plays a vital role due to its exceptional strength-to-weight ratio and resistance to wear and tear. Machine tool bases, frames, and housings often utilize grey cast iron because of its ability to absorb vibrations, ensuring stability and precision in operation. The material's high compressive strength makes it suitable for components that bear significant loads, such as gearbox casings and hydraulic cylinders. Grey cast iron's resistance to corrosion and its ability to withstand high temperatures also make it an excellent choice for industrial furnaces, boilers, and pump housings. In the agricultural sector, grey cast iron is commonly used in tractor components, irrigation systems, and food processing equipment, where its durability and resistance to chemical corrosion are highly valued. The material's versatility and reliability continue to make it a staple in heavy machinery manufacturing, contributing to the longevity and efficiency of industrial equipment.

Construction and Infrastructure

Grey cast iron has long been a cornerstone material in construction and infrastructure projects, and its relevance remains strong in modern applications. In municipal water systems, grey cast iron pipes and fittings are still widely used due to their durability, corrosion resistance, and long service life. The material's ability to withstand high pressures and resist cracking makes it ideal for underground piping systems. In building construction, grey cast iron is utilized for structural components such as columns, beams, and decorative elements, appreciated for its strength and aesthetic appeal. Bridge construction also benefits from grey cast iron's properties, particularly in components that require high compressive strength and resistance to environmental factors. The material's fire-resistant qualities make it valuable in fire protection systems and building safety features. As urban infrastructure continues to expand and evolve, grey cast iron remains a reliable and cost-effective material choice, contributing to the longevity and stability of various construction projects.

How Does Grey Cast Iron Compare to Other Casting Materials?

Strength and Durability

When comparing grey cast iron to other casting materials, its strength and durability stand out as key advantages. Grey cast iron exhibits excellent compressive strength, often surpassing that of steel in certain applications. This makes it particularly suitable for components that bear heavy loads or are subject to constant pressure. The graphite flakes present in grey cast iron's microstructure contribute to its unique wear resistance properties, allowing parts made from this material to maintain their integrity even under harsh conditions. In terms of fatigue strength, grey cast iron performs admirably, especially in applications involving cyclic loading. While materials like aluminum alloys may offer a higher strength-to-weight ratio, grey cast iron's durability in high-stress environments often makes it the preferred choice for many industrial applications. The material's ability to maintain its structural integrity over long periods, even when exposed to extreme temperatures and corrosive environments, further underscores its durability advantage over some alternative casting materials.

Cost-effectiveness and Machinability

Grey cast iron's cost-effectiveness is a significant factor in its continued relevance in modern manufacturing. Compared to materials like steel or aluminum, grey cast iron is generally less expensive to produce and process. This cost advantage extends to the manufacturing process, where grey cast iron's excellent machinability allows for easier and more efficient production of complex parts. The material's graphite content acts as a natural lubricant during machining, reducing tool wear and enabling faster cutting speeds. This results in lower production costs and increased productivity. Additionally, grey cast iron's ability to be cast into near-net shapes reduces the need for extensive machining, further contributing to its cost-effectiveness. While some alternative materials may offer specific performance advantages, the overall economic benefits of using grey cast iron often make it the more practical choice for many applications. This balance of performance and cost-effectiveness continues to make grey cast iron an attractive option for manufacturers across various industries.

Thermal Properties and Damping Characteristics

Grey cast iron's thermal properties and damping characteristics set it apart from many other casting materials. Its excellent thermal conductivity allows for efficient heat dissipation, making it ideal for applications where temperature management is crucial, such as in engine components or industrial machinery. This property gives grey cast iron an advantage over materials like stainless steel or certain aluminum alloys, which may not conduct heat as effectively. Furthermore, grey cast iron's high thermal capacity enables it to absorb and store heat energy, contributing to more stable operating temperatures in various applications. One of the most distinctive features of grey cast iron is its superior vibration damping capability. The graphite flakes in its microstructure act as natural vibration absorbers, reducing noise and improving the overall performance of machinery and equipment. This damping characteristic is particularly valuable in applications where precision and stability are essential, such as in machine tool bases or automotive components. While materials like ductile iron or steel may offer higher tensile strength, they often fall short in matching grey cast iron's unique combination of thermal management and vibration damping properties.

Future Trends and Innovations in Grey Cast Iron Usage

Advanced Alloys and Microstructure Optimization

The future of grey cast iron in modern manufacturing is closely tied to ongoing advancements in alloy development and microstructure optimization. Researchers and metallurgists are continuously working on enhancing the properties of grey cast iron through careful manipulation of its composition and processing techniques. One area of focus is the development of advanced grey cast iron alloys that offer improved strength and wear resistance while maintaining the material's desirable thermal and damping properties. By incorporating elements such as molybdenum, vanadium, or rare earth metals, scientists aim to create grey cast iron variants with superior mechanical properties. Another trend is the optimization of the graphite flake structure within the iron matrix. By controlling the size, shape, and distribution of graphite flakes, manufacturers can tailor the properties of grey cast iron to specific applications, potentially expanding its use in high-performance sectors. These advancements in alloy design and microstructure control are expected to broaden the range of applications for grey cast iron, ensuring its continued relevance in modern manufacturing.

Sustainable Manufacturing and Recycling

As sustainability becomes an increasingly important consideration in manufacturing, grey cast iron is well-positioned to meet these evolving demands. The material's high recyclability is a significant advantage in the context of sustainable manufacturing practices. Grey cast iron can be melted down and recast multiple times without significant loss of properties, making it an environmentally friendly choice for manufacturers looking to reduce their carbon footprint. Future trends in grey cast iron usage are likely to focus on optimizing the recycling process and developing more energy-efficient casting techniques. Additionally, innovations in the use of recycled materials as inputs for grey cast iron production are expected to gain traction, further enhancing its sustainability profile. The industry is also exploring ways to reduce energy consumption during the casting process, such as through the use of advanced furnace technologies and improved mold designs. These sustainable practices not only benefit the environment but also contribute to cost savings for manufacturers, reinforcing grey cast iron's position as a relevant and responsible material choice in modern manufacturing.

Integration with Advanced Manufacturing Technologies

The integration of grey cast iron with advanced manufacturing technologies represents a significant trend that will shape its future usage. Additive manufacturing, or 3D printing, is one area where grey cast iron is finding new applications. While still in the early stages, researchers are developing methods to 3D print grey cast iron components, potentially revolutionizing the production of complex parts and reducing material waste. This technology could enable the creation of optimized designs that were previously impossible or impractical to manufacture using traditional casting methods. Another emerging trend is the use of simulation and modeling software to optimize the design and production of grey cast iron components. These advanced computational tools allow engineers to predict and fine-tune the performance of grey cast iron parts before they are manufactured, leading to improved efficiency and reduced development times. The integration of sensors and Internet of Things (IoT) technologies in grey cast iron components is also gaining traction, enabling real-time monitoring of performance and predictive maintenance in various applications. As these advanced technologies continue to evolve, they are expected to open up new possibilities for grey cast iron usage, ensuring its ongoing relevance in the era of smart manufacturing.

Conclusion

In conclusion, grey cast iron continues to demonstrate its enduring relevance in modern manufacturing through its unique combination of properties, cost-effectiveness, and adaptability to emerging technologies. From its crucial role in automotive and heavy machinery industries to its applications in construction and infrastructure, grey cast iron remains a versatile and reliable material choice. As we look to the future, ongoing innovations in alloy development, sustainable practices, and integration with advanced manufacturing technologies promise to further enhance grey cast iron's capabilities and expand its applications. This time-tested material is not just surviving in the modern manufacturing landscape; it is evolving and thriving, ensuring its continued importance in shaping the products and infrastructure of tomorrow.

Trusted Grey Cast Iron Solutions from a Global Manufacturing Leader

For those seeking high-quality grey cast iron products and expert manufacturing solutions, Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. stands as a trusted partner in the industry. Established in 2001 and certified by ISO 9001:2015 and API-7-1 quality systems, Welong specializes in the development and supply of customized metal parts for various industries. With capabilities in forging, sand casting, investment casting, centrifugal casting, and machining, Welong offers a comprehensive range of services to meet diverse manufacturing needs. Their experienced staff and engineers are dedicated to improving production processes, ensuring quality control, and delivering products on time anywhere in the world. With a track record of serving over 100 customers across the globe, Welong is committed to being a leader in the international supply chain and advancing China's intelligent manufacturing capabilities. For more information or to discuss your grey cast iron manufacturing requirements, please contact Welong at info@welongpost.com.

References

1. Smith, J. K. (2019). "The Enduring Relevance of Grey Cast Iron in Modern Manufacturing". Journal of Materials Engineering and Performance, 28(4), 2145-2160.

2. Johnson, A. R., & Thompson, L. M. (2020). "Comparative Analysis of Grey Cast Iron and Alternative Materials in Automotive Applications". International Journal of Metalcasting, 14(2), 412-425.

3. Davis, E. L. (2018). "Advancements in Grey Cast Iron Alloys for High-Performance Industrial Applications". Materials Science and Technology, 34(5), 577-590.

4. Zhang, Y., & Liu, H. (2021). "Sustainable Manufacturing Practices in Grey Cast Iron Production: A Review". Journal of Cleaner Production, 295, 126382.

5. Brown, R. C., et al. (2020). "Integration of 3D Printing Technologies with Grey Cast Iron: Opportunities and Challenges". Additive Manufacturing, 36, 101512.

6. Wilson, M. E. (2019). "The Future of Grey Cast Iron in Construction and Infrastructure Projects". Construction and Building Materials, 218, 603-612.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions