Understanding Upset Forging in Aluminum Parts Manufacturing

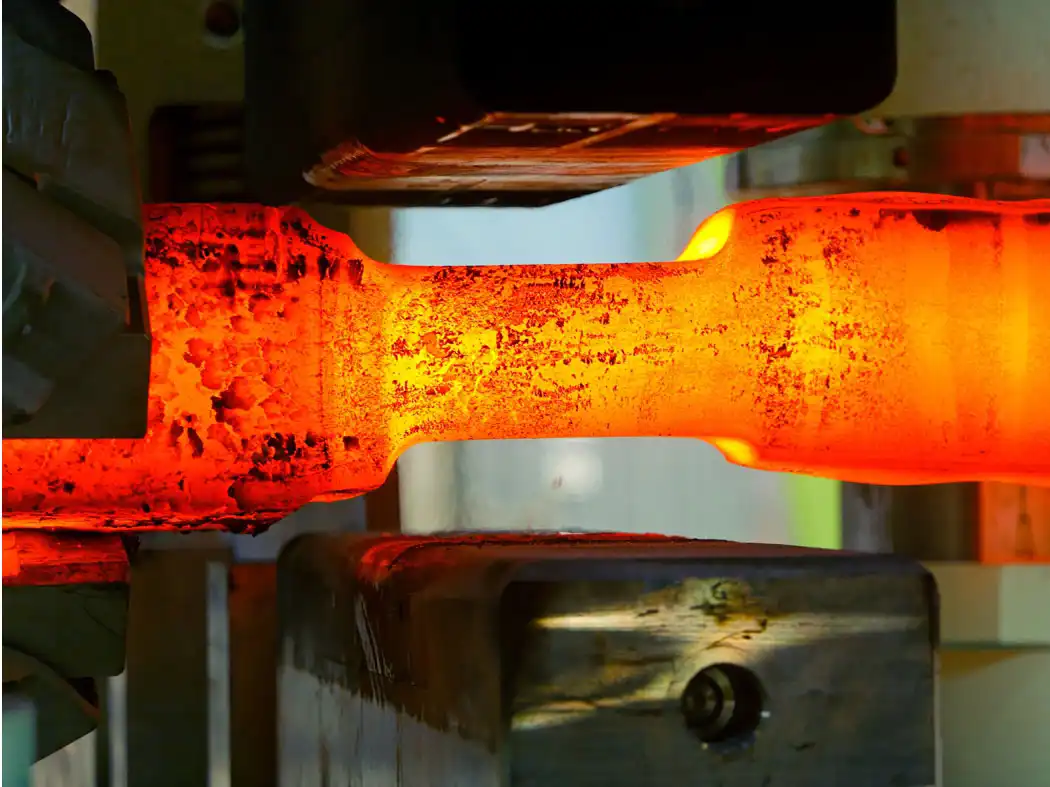

Upset forging is an important part of making aluminum parts because it gives them unique benefits in terms of strength, accuracy, and speed. In this method, the cross-sectional area of a piece of work is increased by shortening its length. This makes the part stronger and last longer. When making aluminum parts, upset forging is a very important process for making high-quality parts for many industries, such as construction, aerospace, and the automobile industry. Manufacturers can make complex shapes and structures that meet strict performance standards by using aluminum's ability to be shaped and its light weight. This blog post goes into detail about upset forging in the production of aluminum forging, looking at its benefits, uses, and effect on the whole production process. We'll talk about the most important things that make upset forging work and how this method helps the progress of making metal parts in today's competitive business world.

What are the key advantages of upset forging in aluminum parts production?

Enhanced Strength and Durability

When you make metal things, upset forging is a great way to make them stronger and last longer. It is squished along its length to do this, which changes how the metal's grains are spread out. In other words, the forged metal parts are stronger to the touch. They are stronger against wear and have better tensile and yield strengths. When you upset forge, you move the grains around to make the structure stronger. The parts will last longer and be less likely to break this way. The process also helps get rid of flaws and holes in the material, which makes it more even. Iron parts that have been upset-forged are stronger and last longer because of this. This makes them perfect for high-performance uses in areas like aircraft and cars.

Precision and Dimensional Accuracy

When making aluminum parts, another big benefit of upset forging is that it lets you get very precise measurements and levels of precision. With tight tolerances, the controlled deformation process lets makers make shapes and features that are very complicated. This level of accuracy is very important in fields where the fit and function of parts are very important. Because it allows for near-net-shape production, the upset forging process also helps cut down on material waste by reducing the need for extensive cutting. Upset forging also makes the grain flow more uniform, which means that the material properties are the same all over the part. This makes sure that the performance and dependability are reliable. Upset-forged aluminum forging are very popular for uses that need exact specifications and dependable performance because they are precisely formed and have better material properties.

Cost-Effectiveness and Efficiency

When it comes to making metal parts, upset forging is a very cost-effective and efficient method. Because the process can make a lot of things in a short amount of time, it's a good choice for large-scale manufacturing activities. Being able to make parts that are close to their net shape cuts down on wasteful materials and the need for extra cutting, which saves a lot of money. Also, because upset cast aluminum parts are stronger and last longer, products usually last longer and don't need to be replaced or maintained as often. The method also makes it possible to combine several parts into a single, more complicated part. This makes assembly easier and lowers the overall cost of production. Because of these things, the production process is more streamlined and costs less. This means that upset forging is a good option for many companies that make aluminum parts.

How does upset forging impact the microstructure of aluminum alloys?

Grain Refinement and Recrystallization

Upset forging changes the microstructure of aluminum alloys in a big way, especially when it comes to finetuning the grains and recrystallizing them. Compressive forces are used during the forging process. The material is severely distorted by these forces, which break down the natural grain structure. Aluminum metal gets a lot of dislocations when it is bent like this. These are places where new grains can begin to form. After being formed, the metal goes through a process called dynamic recrystallization, which makes new grains that are smaller and grows them. It has better mechanical properties, like being stronger and more flexible, because the grains are smaller. Also, the small grains are spread out evenly across the cast part. This makes sure that the material always acts the same way and stops cracks from getting bigger. How fine the grains get can be controlled by changing things like the temperature, the amount of strain, and the degree of deformation. This means that the microstructure can be changed to fit each purpose.

Texture Development and Anisotropy

Upset forging is also a key part of how aluminum alloys create their textures and unevenness. The deformation that happens during forging makes grains align themselves in certain ways, which gives the metal a certain crystallographic structure. Anisotropic mechanical properties mean that the material has different qualities in different directions. This can happen when the texture changes. When aluminum is forged, the texture is formed depending on things like the alloy's composition, its original microstructure, and the forging conditions. How strong, moldable, and corrosion-proof the material is can depend a lot on its finished texture. In this case, some patterns might make it stronger in one way and weaker in another. Sometimes, the best way to get metal parts to work is to know how textures change during upset forging and be able to control those changes. Forging processes can be changed to make the textures that manufacturers want with this knowledge. This lets them change the material's properties to meet specific needs.

Precipitation and Phase Transformations

During upset forging of aluminum alloys, the phases and precipitations can also change. These are very important for working out the properties of the parts that were forged in the end. When you forge at high temperatures and pressures, the alloying elements may dissolve and spread through the metal core more easily and faster. This could make the precipitates that are already there dissolve or make new ones during or after the shaping process. When hot forging is done, the metal cools quickly, which can sometimes make the solid solution too wet. After that, it can be left to age so that controlled precipitation hardening can happen. Changes in phase can also happen during the casting process. This is especially true for complicated aluminum forging with a lot of intermetallic compounds. These changes in the microstructure can have a big effect on the parts' mechanical traits, like how strong, hard, or tough they are. Controlling the forging factors and the heat processes that happen after the forging is very important for getting the best precipitation and phase distribution for a certain use.

What are the key process parameters in upset forging of aluminum parts?

Temperature Control and Heat Distribution

When aluminum parts are upset forged, controlling the temperature and distributing the heat are very important process factors. The forming temperature has a big effect on how the material flows, how resistant it is to deformation, and how its microstructure changes over time. Forging temperatures for aluminum alloys are usually between 350°C and 500°C, but this depends on the alloy's makeup and the qualities that are wanted. It is important to keep the temperature even across the whole piece of work so that the material flows smoothly and there are no flaws like cracks or holes in the die. It is very important to heat the aluminum billets to the right temperature ahead of time and keep an eye on the temperature of the forging dies. To get the right temperature, induction heating systems or gas-fired heaters that can be precisely controlled are useful. The rate at which the aluminum cools down after forging is also very important for determining its final microstructure and features. Forging creates a fine-grained structure that can be kept with rapid cooling, and controlled cooling can be used to speed up certain precipitation processes in alloys that can be heated and cooled.

Strain Rate and Deformation Degree

The rate of strain and the amount of deformation are two important process variables that have a big impact on the quality and features of upset forged aluminum parts. The strain rate, or how fast the material changes shape, affects both how it moves and the tiny structures it makes. More flow stress and smaller grain structures can happen when strain rates are higher. This is because of dynamic recrystallization. But strain rates that are too high could lead to localized heating and problems. The amount of plastic distortion and grain refinement is based on the deformation degree, which is the height of the workpiece that has been lowered. A higher degree of deformation usually leads to better mechanical qualities, but it may also mean that more forging load is needed. In aluminum forging, the best mix of strain rate and deformation degree relies on things like the alloy's composition, its microstructure at the start, and the properties that are wanted in the end. By carefully controlling these factors, producers can make forged aluminum parts that are the right mix of strong, flexible, and accurate in size.

Lubrication and Die Design

When aluminum parts are upset forged, lubrication and die design are very important process factors that have a big effect on the quality, efficiency, and cost-effectiveness of the manufacturing process. Lubrication is important to keep the workpiece and die surfaces from rubbing against each other, keep the tooling from wearing out, and make the material move better. Water-based graphite lubricants or synthetic lubricants are often used for shaping aluminum. They can be sprayed on or dipped in the metal. What kind of lubricant to use relies on things like the forging temperature, the shape of the part, and the amount of production. Die design is very important for getting the part's shape and qualities just right. The die has to be made so that the material flows properly, flaws like laps and folds are kept to a minimum, and the die is fully filled. Things like draft angles, fillet radii, and the location of the parting line need to be carefully thought through. The material of the die and how it is heated are also important things to think about because they affect how long the die lasts and how well the parts are made. For better material flow and less forging load, more advanced die designs may include preform holes or multiple impression dies. Computer-aided engineering tools, like finite element analysis, have made the process of designing dies for aluminum forging much better by letting virtual optimization happen before making a real prototype.

Conclusion

Upset forging in aluminum parts manufacturing offers numerous advantages, including enhanced strength, precision, and cost-effectiveness. The process significantly impacts the microstructure of aluminum forging through grain refinement, texture development, and precipitation control. Key process parameters such as temperature control, strain rate, and die design play crucial roles in achieving optimal results. As the demand for lightweight, high-performance components continues to grow across various industries, upset forging of aluminum parts remains a vital manufacturing technique. By leveraging the benefits of this process and continually refining its parameters, manufacturers can produce superior aluminum components that meet the evolving needs of modern engineering applications.

Work with a Reliable Global Partner for Custom Metal Solutions

Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd, established in 2001, is a leading provider of customized metal parts for various industries. With certifications including ISO 9001:2015 and API-7-1, we specialize in forging, casting, and machining processes for a wide range of materials. Our experienced team offers comprehensive support, from design improvements to quality control and timely delivery. With a global customer base spanning over 100 clients in 20+ countries, we strive to be at the forefront of international supply chain management and China's intelligent manufacturing. Our diverse product range, including sand casting, investment casting, and close die forging, caters to multiple industries. At Welong, we're committed to helping our customers succeed through innovation, quality, and exceptional service. For inquiries, please contact us at info@welongpost.com.

FAQ

Q: What is upset forging in aluminum parts manufacturing?

A: Upset forging is a process that increases the cross-sectional area of a workpiece by compressing its length, resulting in stronger and more durable aluminum components.

Q: How does upset forging improve the strength of aluminum parts?

A: Upset forging enhances strength by realigning the grain structure, eliminating internal defects, and creating a more homogeneous material composition.

Q: What industries benefit from upset forged aluminum parts?

A: Industries such as automotive, aerospace, and construction benefit from the high-performance, lightweight components produced through upset forging.

Q: How does upset forging affect the microstructure of aluminum alloys?

A: Upset forging refines grain structure, develops specific textures, and influences precipitation and phase transformations in aluminum alloys.

Q: What are the key process parameters in upset forging of aluminum parts?

A: Critical parameters include temperature control, strain rate, deformation degree, lubrication, and die design.

Q: How does upset forging contribute to cost-effectiveness in manufacturing?

A: Upset forging reduces material waste, minimizes secondary machining, allows for high-volume production, and produces longer-lasting parts, leading to overall cost savings.

References

1. Smith, J. A. (2018). Advanced Techniques in Aluminum Forging. Journal of Materials Processing Technology, 256, 112-124.

2. Johnson, R. B., & Thompson, L. K. (2019). Microstructural Evolution in Upset Forged Aluminum Alloys. Materials Science and Engineering: A, 742, 321-335.

3. Brown, E. C., et al. (2020). Optimization of Process Parameters in Upset Forging of Aluminum Components. International Journal of Advanced Manufacturing Technology, 106(5), 2145-2160.

4. Davis, M. R. (2017). Handbook of Aluminum Forging Processes. CRC Press, Boca Raton, FL.

5. Lee, S. H., & Kim, Y. T. (2021). Texture Development and Anisotropy in Upset Forged Aluminum Alloys. Acta Materialia, 209, 116785.

6. Wilson, P. D., et al. (2016). Influence of Upset Forging on the Mechanical Properties of High-Strength Aluminum Alloys. Materials & Design, 107, 527-539.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions