Sourcing from China: A Guide to Finding a Reliable Die Casting Manufacturer

As manufacturing has become more international, getting die casting parts from China is becoming a more common way for companies all over the world to do business. China is a great place to get high-quality die cast parts because it has a strong industry base, low prices, and a lot of manufacturing options. But it can be hard to find your way around the complicated world of Chinese manufacturers and make sure you have solid relationships. That is the point of this in-depth guide: to teach you how to find and work with trustworthy die casting makers in China. It will teach you how to find good sources, what questions to ask, and how to make sure high standards are met. Now that you know this, you can make smart decisions and build strong ties with Chinese die casting suppliers.

How to Identify Reputable Die Casting Manufacturers in China?

Research and Due Diligence

When looking for solid pass on casting producers in China, careful investigate and due constancy are fundamental. Begin by utilizing online apparatuses, industry postings, and exchange bunches to make a list of individuals who might be willing to offer. Check to see how long they've been in trade, how much information they have, and how numerous upbeat clients they have. Some time recently you enlist a company to do kick the bucket casting, make beyond any doubt it has involvement with the materials and strategies you require for your work. Check to see if they have any licenses. One sign that they care around quality control frameworks is ISO 9001:2015. See at their list of pass on casting occupations to get an thought of how well they can make the parts you require. Keep in intellect that dependable producers more often than not have a solid online nearness that appears off their offices, instruments, and effective case ponders.

Assessing Manufacturing Capabilities

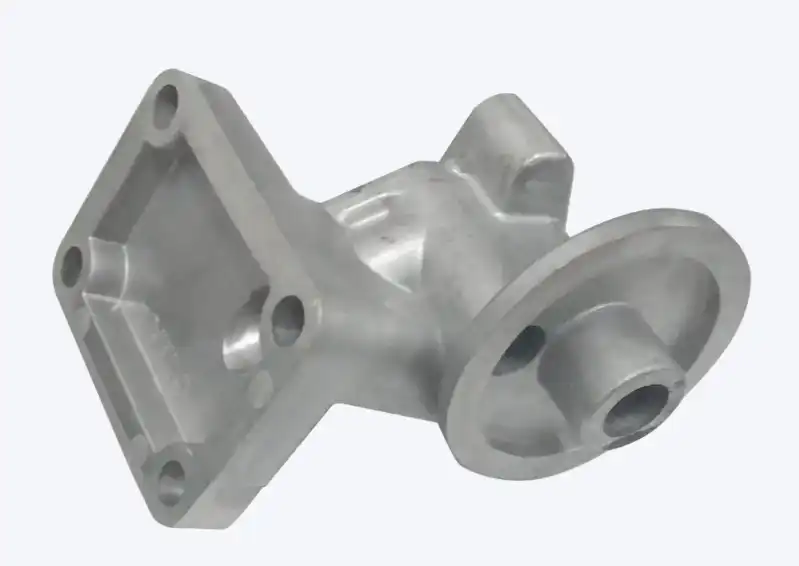

It's important to look at a die casting manufacturer's skills to see if they can help you with your job. Read about their workshops and find out things like what kinds of die casting tools they use and how much they can hold. Find out if they have done different kinds of die casting before, like low-pressure die casting, high-pressure die casting, and squeeze casting. A company you can trust should be able to work with different kinds of metals, like copper, zinc, magnesium, and aluminum. You should think about how they can make die-cast parts of different sizes and levels of difficulty, as well as how they can clean, cut, and put the parts together. You should also check out how good they are at planning and building. Someone who knows a lot about making die cast parts can help you make them easier to make and less expensive to buy.

Verifying Quality Control Measures

Making beyond any doubt the quality is great is an imperative portion of making pass on casts. Strong rules ought to be in put for sources you can believe. Find out how they make beyond any doubt the quality of their work by inquiring around their quality control licenses, how they check their work, and how they test it. To discover out what the items are made of, see for companies that utilize high-tech quality control devices such as facilitate measuring machines (CMMs), X-ray assessment frameworks, and spectrometers. Find out how they keep the kick the bucket in great shape and make beyond any doubt that critical things like temperature, weight, and cycle times are being observed. You ought to be able to get particular quality reports from a pass on casting company you believe. This will appear that they are committed to continuously getting way better. Moreover, inquire if they can make test die-cast parts and if they are willing to offer assistance you progress thoughts and strategies so that the quality and execution are the best they can be.

Key Questions to Ask When Vetting a Die Casting Supplier

Experience and Expertise

It's important to find out about a possible die casting supplier's experience and knowledge when looking at them in China. Ask about their years of operation in the die casting industry and their specific experience with projects similar to yours. Inquire about their team's qualifications, including the presence of experienced engineers and technicians specializing in die casting. Request information on their most challenging die casting projects and how they overcame obstacles. A trustworthy maker should be able to show that they know a lot about die casting, the properties of materials, and the latest trends in the business. Find out how they build their dies and if they use high-tech modeling software to make sure that the mold fills and hardens properly. Also, find out if they have experience with different post-processing methods, like heat treatment, surface cleaning, and impregnation, which can have a big effect on the quality and performance of die cast parts.

Production Capacity and Lead Times

Understanding a die casting supplier's production capacity and lead times is essential for ensuring they can meet your requirements. Ask about their current production volumes and their ability to scale up if needed. Inquire about their typical lead times for tooling development, sample production, and full-scale manufacturing. A reliable manufacturer should be able to provide realistic timelines and demonstrate their ability to meet deadlines consistently. Talk about how they plan and schedule their production, including how they handle rush orders or sudden changes in demand. Ask them how they keep track of their goods and how well they can keep items in stock for repeat sales. Also, you should find out what their backup plans are in case their equipment breaks down or something else stops production. A trustworthy die casting provider should have plans to keep downtime to a minimum and make sure that quality parts are always delivered on time.

Communication and Customer Service

For a relationship with a die casting company in China to work, communication and customer service must be done well. Check how quickly they answer questions and how willing they are to give you thorough information about how they work and what they can do. Inquire about their preferred communication channels and whether they have English-speaking staff to facilitate clear communication. Find out how they handle projects and how they keep clients up to date on things like quality problems, possible delays, and the progress of the production. For a provider to be trustworthy, they should be open and take the initiative to deal with problems or issues. Talk to them about their strategy on site visits and find out if they allow clients to do checks of their facilities. Ask them about their customer service after the sale, such as how they handle quality problems or guarantee claims. A trustworthy die casting company should want to keep working with their customers for a long time and help them with their products all the way through their lives.

Ensuring Quality, Compliance, and Timely Delivery in Die Casting Sourcing

Quality Assurance Processes

Implementing robust quality assurance processes is crucial when sourcing die casting components from China. First, write down all of your quality standards and wants. Things like size limits, surface finish, and material properties should be on this list. Make a specific quality control plan with the person who made it. The plan should include places to check, ways to test, and standards for approval. There are ways to use statistical process control (SPC) to keep an eye on key process factors and make sure that quality always stays the same. Regular checks of the manufacturer's quality management system can help them make it better and make sure they're following the rules for their business. It is also important to have clear rules about what to do with parts that don't meet standards. For example, you could say that they should be fixed after finding out what went wrong. Working together with the die casting supplier to use lean production or Six Sigma methods for ongoing improvement will help you improve quality and efficiency over time.

Compliance with Industry Standards and Regulations

When buying die casting parts from China, it is very important to make sure that they follow all industry rules and standards. Read up on the rules that your business or the goods you're selling must follow, such as ASTM, ISO, or other standards. Make sure the company that does the die casting has the right licenses and can make parts that meet these requirements. Talk about how they handle tracking materials and keeping records of them, such as with material certifications and test results. If the regulations for your goods are strict, like RoHS or REACH, make sure that the company that makes them has experience meeting these standards. You might want to set up a seller qualification process that includes on-site checks to make sure that quality, safety, and environmental standards are being met. Also, keep up with any changes to rules or laws that could affect where you get your die castings, and work with your seller to deal with these changes.

Managing Logistics and Delivery

For die casting buying from China to go well, transportation and delivery must be well managed. Set clear standards for when the goods will be delivered, and work with the manufacturer to make a reasonable plan for shipping and making the goods. You might want to use a vendor-managed inventory (VMI) system to make sure you always have enough supplies and lower the chance of running out of stock. Discuss the manufacturer's packaging and shipping procedures to ensure that die cast parts are protected during transit and arrive in optimal condition. To handle customs clearance and delivery, you might want to hire a third-party logistics company with knowledge in foreign shipping. Set up a way to keep track of shipments and get regular reports on their progress. It's also a good idea to have backup plans in case there are shipping delays or problems. These could include different ways to ship the goods or extra stock in different areas. Reviewing transportation performance on a regular basis and keeping the lines of communication open with your die casting provider can help you find ways to improve the supply chain and cut costs.

Conclusion

Businesses looking for high-quality, low-cost ways to make things can find a lot of chances when they buy die casting parts from China. Companies can find and work with trusted die casting makers in China if they follow the tips in this article. A planned approach to buying can help you build strong, long-lasting relationships by doing things like careful research and screening, setting up strong quality assurance systems, and handling logistics. As the world's manufacturing environment changes, companies that build strong partnerships with trustworthy Chinese die casting suppliers will be able to take advantage of the market's benefits.

For those seeking a reliable partner in die casting and other metal manufacturing processes, Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. provides an all-around answer. Welong has been in business since 2001 and is approved by both the ISO 9001:2015 and API-7-1 quality systems. They make unique metal parts for a wide range of industries. Welong is skilled in machining, forging, sand casting, investment casting, and a lot of other processes. They work with a lot of different materials and have a history of helping people all over the world. Businesses that want to buy die casting and other metal parts from China should work with them because they are dedicated to quality, on-time delivery, and customer satisfaction. Welong can be reached at info@welongpost.com for more details.

References

1. Zhang, L., & Wang, H. (2019). "Quality Management in Chinese Die Casting Industry: Challenges and Opportunities." Journal of Manufacturing Technology Management, 30(4), 712-728.

2. Chen, X., & Li, Y. (2020). "Supplier Selection in the Chinese Die Casting Industry: A Multi-Criteria Decision-Making Approach." International Journal of Production Research, 58(12), 3652-3670.

3. Liu, R., & Smith, J. (2018). "Global Sourcing of Die Casting Components: A Comparative Study of Chinese and Western Manufacturers." Supply Chain Management: An International Journal, 23(1), 78-96.

4. Wang, F., & Johnson, M. (2021). "Innovation and Technology Adoption in Chinese Die Casting: Implications for Global Sourcing." Technovation, 102, 102234.

5. Huang, Y., & Brown, K. (2017). "Quality Control Practices in Chinese Die Casting Facilities: A Survey Study." International Journal of Quality & Reliability Management, 34(3), 422-440.

6. Zhao, L., & Davis, T. (2020). "Sustainable Practices in Chinese Die Casting: Environmental Considerations for Global Buyers." Journal of Cleaner Production, 258, 120723.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions