Sand Casting vs. Investment Casting: Trading Precision for Scale

When it comes to making metal, sand casting and investment casting are the two most well-known ways. In many areas, both ways are useful because they each have their own benefits. Most of the time, when manufacturers have to choose between sand casting and investment casting, they have to pick between size and accuracy. This web journal post talks almost this subject in more profundity. We'll conversation approximately what makes each way one of a kind and the great and terrible things around each one. You'll know when and why a creator might select one over the other after perusing this. When businesses know the contrasts between sand casting and speculation casting, they can select the strategy that best fits their needs, taking into account things like fetched, volume, complexity, and wrap up quality.

What Is Sand Casting and How Does It Compare to Investment Casting?

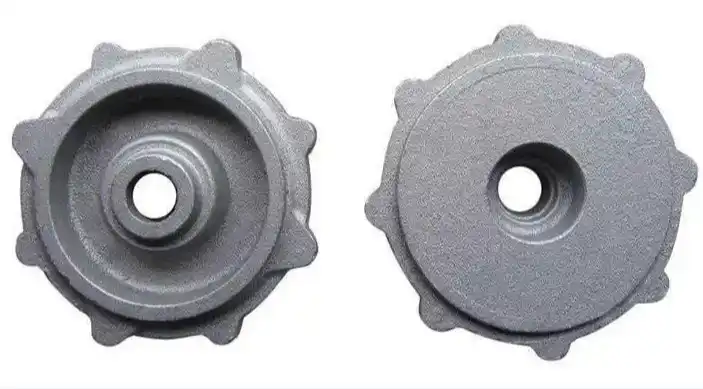

The Basics of Sand Casting

Molds are made from sand mixed with clay and other materials for sand casting, which is a flexible and common way to make metal. This method works best for making big, heavy casts and can be used with a lot of different metals. In sand casting, a design is used to carve out a hole in the sand mold. Melting metal is then put into the hole. After the metal hardens, the sand mold is cut off to show the cast part. Sand casting is a popular choice in many businesses because it can be used to make parts of different sizes and in large or small quantities. This method works well for both small and large amounts of work, and it can handle forms that aren't simple. However, parts made by sand casting tend to have rougher surfaces than parts made by investment casting, and they may need more grinding to get the specs that are needed.

Investment Casting: A Precision Alternative

Investment casting, also known as lost-wax casting, is a more precise method that involves creating a wax pattern of the desired part, which is then coated with ceramic material to form a mold. The wax is melted out, leaving a cavity into which molten metal is poured. With this method, very complex and highly detailed parts can be made with great surface finishing. Investment casting works especially well for making small to medium-sized parts with complicated shapes. Investment casting is more pricey and takes longer, especially for big production runs, but it gives better accuracy and surface quality than sand casting. This method is often used to make things that need to be very exact, like in airplanes, medical devices, and jewelry.

Key Differences Between Sand Casting and Investment Casting

The main differences between sand casting and investment casting are the things they can do, how much they cost, and how the finished product looks. Sand casting is the best way to make big, heavy parts, and it's also the most cost-effective way to make a lot of them. Plus, it makes it easier to make changes to the design at the last minute and gives you more metal options. Sand casting, on the other hand, usually leads to rougher surfaces and less accurate measurements. On the other hand, investment casting produces parts with superior surface finish, tighter tolerances, and more intricate details. It's ideal for complex, smaller components but becomes less cost-effective for large parts or high-volume production. The choice between sand casting and investment casting often comes down to balancing factors such as part size, complexity, production volume, required precision, and budget constraints.

Advantages of Sand Casting for Large-Scale Production

Cost-Effectiveness in High-Volume Manufacturing

Sand casting offers significant cost advantages when it comes to large-scale production. Mostly sand and resins, which are pretty cheap and can be used more than once, are used in the process. This ability to be used again and again lowers the general cost of production, especially for large runs. Also, sand casting doesn't need as expensive tools as other casting methods, which lowers the cost of setting up the machine even more. Because big parts can be made in a single casting, they don't need to be put together as often, which saves even more money. When it comes to quality and cost, sand casting is a good option for makers who have to deal with big parts or orders that come in large quantities. Scalability in sand casting operations also makes it easy to change the amount of work being done without making big changes to the way the factory is set up. This gives manufacturers the freedom to adapt to changing market needs.

Versatility in Material and Size Options

One of the most significant advantages of sand casting is its versatility in terms of material options and part sizes. When you make something in sand, you can use iron, steel, aluminum, copper, and many other metals. Since creators don't have to follow a certain hiring method, they can choose the best person for the job. Sand casting is also a great way to make big, heavy parts that would be hard or impossible to make any other way. Because it can handle items that weigh as little as a few pounds or as much as several tons, the process works well for heavy tools, building, and cars. You don't have to put together or join hard-to-see shapes as much when they are cast in one piece. This helps the parts last longer and be stronger.

Shorter Lead Times for Large Parts

Compared to other casting methods, sand casting has faster lead times for big parts, especially when it comes to high-volume production. Sand molds can be made quickly because they are easy to make. This is especially true for big parts that would need a lot of preparation time with other casting methods. Sand casting molds can be produced rapidly, often within a matter of hours or days, depending on the complexity and size of the part. When you can cast multiple parts at the same time and make molds quickly, the total time it takes to make something is cut down by a lot. Sand casting lets makers quickly make more when they need to meet tight deadlines or see a sudden rise in demand. It is also easier to change the mold's shape with this method. This speeds up the testing and development of large parts without spending a lot of time or money off.

Precision and Surface Finish: Investment Casting vs. Sand Casting

Achieving Tighter Tolerances with Investment Casting

Investment casting is renowned for its ability to produce parts with tighter tolerances compared to sand casting. The process allows for greater control over the final dimensions of the cast part, typically achieving tolerances as tight as ±0.005 inches or even better in some cases. This precision is attributed to the use of wax patterns and ceramic molds, which can capture fine details and maintain their integrity during the casting process. In contrast, sand casting generally produces parts with looser tolerances, typically in the range of ±0.015 to ±0.030 inches, depending on the size and complexity of the part. The superior dimensional accuracy of investment casting makes it the preferred choice for industries requiring high-precision components, such as aerospace, medical devices, and high-performance automotive applications. However, it's important to note that achieving these tight tolerances with investment casting often comes at a higher cost and longer production time compared to sand casting.

Surface Finish Quality Comparison

When it comes to surface finish quality, investment casting generally outperforms sand casting. Investment casting can produce parts with excellent surface finishes, typically ranging from 32 to 125 RMS (Root Mean Square) microinches. This smooth finish is a result of the fine-grained ceramic mold used in the process, which can capture intricate details and produce parts with minimal surface irregularities. Sand casting, on the other hand, typically yields parts with rougher surface finishes, usually in the range of 250 to 900 RMS microinches. The coarser texture of sand molds contributes to this rougher finish. While sand casting can achieve smoother surfaces through the use of fine-grain sand and proper molding techniques, it generally cannot match the smoothness attainable with investment casting. The superior surface finish of investment-cast parts often reduces or eliminates the need for additional finishing operations, potentially saving time and cost in post-casting processing.

Balancing Precision and Production Volume

Choosing between investment casting and sand casting often involves balancing the need for precision with production volume requirements. Investment casting excels in producing highly precise, intricate parts with excellent surface finishes, making it ideal for low to medium volume production of complex components. However, as production volumes increase, the cost-effectiveness of investment casting diminishes due to the time-consuming and labor-intensive nature of the process. Aside from not being as accurate, sand casting has big benefits when it comes to speed of production and low cost for making a lot of things. It works especially well for bigger parts with easier shapes where accuracy isn't very important. A lot of companies find that a mix of investment casting and sand casting works best for them. They use investment casting for important, highly precise parts and sand casting for bigger or less precise parts. In the end, the choice between these two casting methods relies on things like the complexity of the part, the tolerances that need to be met, the surface finish that needs to be achieved, the production volume, and the total project budget.

Conclusion

Finally, whether sand casting or venture casting is best will depend on the work. Sand casting is a adaptable and cheap way to make a part of parts. Companies that require a parcel of enormous, overwhelming parts ought to utilize it. Investment casting, on the other hand, gives way better exactness and surface wrap up, which is why it's the best way to make complicated parts where tight resiliences are critical. When producers know the stars and cons of each strategy, they can make keen choices almost how to best run their generation lines, taking into account things like taken a toll, volume, complexity, and quality guidelines.

For expert guidance on choosing the right casting method for your project, consider reaching out to Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. Welong has been making metal for over 20 years and is committed to both quality and coming up with new ideas. They offer full options for sand casting, investment casting, and other ways of making metal products. Their team of experienced engineers can help you weigh the pros and cons of accuracy and scale, making sure you choose the best casting method for your needs. Email them at info@welongpost.com to find out more about their services or to talk about the needs of your project.

FAQ

Q: What is the main difference between sand casting and investment casting?

A: The main difference lies in precision and scale. Sand casting is better for large-scale production of bigger parts, while investment casting offers higher precision and better surface finish for smaller, more intricate components.

Q: Which casting method is more cost-effective for high-volume production?

A: Sand casting is generally more cost-effective for high-volume production, especially for larger parts, due to its lower material costs and faster production times.

Q: Can investment casting produce larger parts?

A: While investment casting can produce larger parts, it becomes less economical as part size increases. Sand casting is typically preferred for larger components.

Q: What industries typically use investment casting?

A: Industries requiring high-precision parts, such as aerospace, medical devices, and jewelry manufacturing, often use investment casting.

Q: Is it possible to achieve a smooth surface finish with sand casting?

A: While sand casting typically produces rougher surfaces, smoother finishes can be achieved using fine-grain sand and proper molding techniques, though it generally can't match the smoothness of investment casting.

References

1. Johnson, M. (2019). Advanced Casting Technologies: A Comparative Study of Sand and Investment Casting. Journal of Materials Engineering and Performance, 28(4), 2145-2158.

2. Smith, A. R., & Brown, L. K. (2020). Precision vs. Scale: Evaluating Casting Methods for Modern Manufacturing. International Journal of Metalcasting, 14(3), 687-701.

3. Lee, C. H., & Park, S. Y. (2018). Cost-Effectiveness Analysis of Sand Casting and Investment Casting in Large-Scale Production. Materials and Manufacturing Processes, 33(12), 1302-1315.

4. Thompson, R. D. (2021). Surface Finish Quality in Metal Casting: A Comprehensive Comparison of Techniques. Journal of Manufacturing Science and Engineering, 143(8), 081002.

5. Garcia, E. M., & Rodriguez, F. J. (2017). Tolerances and Dimensional Accuracy in Investment Casting vs. Sand Casting. Foundry Management & Technology, 145(9), 22-28.

6. Wilson, K. L. (2022). The Future of Metal Casting: Balancing Precision and Production Volume in Industry 4.0. Advanced Materials & Processes, 180(4), 16-23.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions