Gravity Die Casting vs. High-Pressure Die Casting: An Application Guide

Two well-known metal casting methods stand out for how well and accurately they work: gravity die casting and high-pressure die casting. They are both useful and useful in different situations because they are different. This guide goes into great depth about how gravity die casting and high-pressure die casting are different and what the best uses are for each. Manufacturers can pick the best casting method for their needs if they know how they are different. They can think about things like the material's qualities, how hard the plan is, how many are made, and how much it costs. If you work in the car, military, or consumer goods industries, this application guide will help you learn more about die casting and improve the way you make things.

What Is Gravity Die Casting and How Does It Differ from High-Pressure Die Casting?

Definition and Basic Principles of Gravity Die Casting

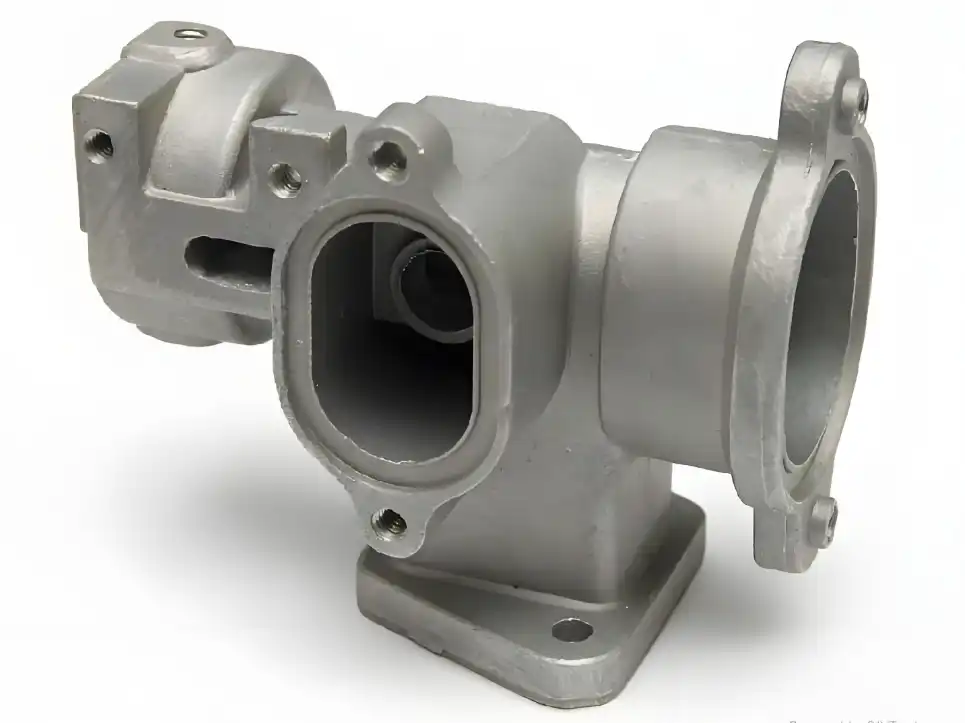

Gravity die casting is a metal casting process that utilizes the force of gravity to fill permanent molds with molten metal. In this method, molten metal is poured into a mold cavity from above, allowing it to flow downward and fill the mold under its own weight. The gravity die casting method is easy to understand and relies on natural forces. This makes it a quick and inexpensive way to make medium-sized metal parts. High-pressure die casting forces liquid metal into the mold with high pressure. Gravity die casting, on the other hand, uses the metal's own weight and fluidity to fill the form correctly. Because of this basic difference in the way the mold is filled, each casting method has its own pros and cons, which affects how well it works for different production and application situations.

Key Differences Between Gravity and High-Pressure Die Casting

The primary distinction between gravity die casting and high-pressure die casting lies in the way molten metal is introduced into the mold cavity. In gravity die casting, the metal flows naturally under the influence of gravity, while high-pressure die casting employs significant force to inject the metal rapidly into the mold. There are other differences between the two processes besides the way the fillings are done. Parts made by gravity die casting usually have lower internal loads and fewer trapped gases. This means they have better mechanical qualities and less porosity. High-pressure die casting, on the other hand, has shorter cycle times and can make more complicated parts with thin walls. When deciding between gravity die casting and high-pressure die casting, things like the part's size, complexity, production volume, and the surface finish that is wanted are often important. Each method is better at certain tasks.

Typical Applications and Industries for Each Casting Method

There is a lot of use for gravity die casting in fields that need medium-sized parts with good mechanical qualities. Parts for cars, like cylinder heads, engine blocks, and transmission housings, can be made very well with it. In the airplane business, gravity die casting is also used to make parts like rotor blades and structure bits. On the other hand, high-pressure die casting is often the best way to make smaller, more complicated parts with thin walls, like electrical enclosures, car trim parts, and housings for home appliances. High-pressure die casting is often used in the telecommunications and consumer electronics industries to make lightweight, highly detailed parts. Knowing the common uses and businesses for each casting method helps makers match their output needs with the best technique, making sure their processes are the best in terms of quality, efficiency, and cost-effectiveness.

Advantages of Gravity Die Casting for Medium-Volume Production

Enhanced Mechanical Properties and Reduced Porosity

Gravity die casting has big benefits when it comes to mechanical qualities and less porosity, which makes it a great choice for making things in medium quantities. Because the filling rate is slower in gravity die casting, the solidification process can be better controlled. This makes the microstructure more regular and the mechanical properties better. This quality is especially helpful for parts that need to be strong and last a long time. Also, the natural flow of molten metal in gravity die casting makes it less likely that gases and air pockets will get caught, which means the end product has fewer holes. The lower porosity not only makes the cast parts stronger, but it also makes the surface finish and quality better all around. And because of these benefits, gravity die casting is perfect for making parts that need to work well and be reliable, like parts for cars and spacecraft.

Lower Tooling Costs and Longer Die Life

One of the significant advantages of gravity die casting in medium-volume production is its lower tooling costs and extended die life. The molds used in gravity die casting are subjected to less stress and wear compared to those in high-pressure die casting, as they don't need to withstand the high injection pressures. Because the tools aren't under as much stress, the dies last longer, so makers can make more parts before they need to repair or fix the molds. Gravity die casting is a good choice for medium-volume production runs because the cost of the tools is lower, so the original investment in making the mold can be spread out over a bigger number of parts. Also, gravity die casting's simpler mold design often makes upkeep and repairs easier, which cuts down on downtime and total production costs.

Flexibility in Design and Material Selection

When compared to high-pressure die casting, gravity die casting gives you more choices when it comes to style and material. It is possible to make parts with different wall thicknesses and more complicated internal shapes with this method, which is not always possible with high-pressure die casting. Because of this design freedom, makers can make parts that have the best weight distribution and structural stability. Additionally, gravity die casting is compatible with a wider range of alloys, including those with higher melting points or that are prone to rapid solidification. Manufacturers can now choose the materials that best meet their needs, whether they need stronger materials, materials that don't rust, or materials that let heat flow through them. You can make things in middle amounts with gravity die casting in a lot of different fields because it works with a lot of different materials and shapes.

Material, Design, and Cost Considerations in Die Casting Methods

Alloy Selection and Its Impact on Casting Method Choice

The selection of alloys plays a crucial role in determining the most suitable die casting method for a given application. Gravity die casting is particularly well-suited for alloys with higher melting points and those that require slower cooling rates to achieve optimal mechanical properties. Aluminum alloys, copper alloys, and some magnesium alloys are commonly used in gravity die casting due to their excellent fluidity and ability to produce high-quality castings with minimal porosity. On the other hand, high-pressure die casting is often preferred for alloys with lower melting points and faster solidification rates, such as zinc alloys and certain aluminum alloys. The choice of alloy can significantly impact the final product's characteristics, including strength, durability, and surface finish. When selecting between gravity die casting and high-pressure die casting, manufacturers must carefully consider the material properties and how they align with the desired outcomes of the casting process.

Design Constraints and Possibilities in Gravity vs. High-Pressure Die Casting

Design considerations play a significant role in choosing between gravity die casting and high-pressure die casting. Gravity die casting offers greater flexibility in creating parts with varying wall thicknesses and more complex internal geometries. This method is particularly suitable for components that require uniform solidification and minimal internal stresses. However, gravity die casting may have limitations in producing extremely thin-walled parts or intricate external details. In contrast, high-pressure die casting excels in producing thin-walled components with complex external features and fine surface details. The high injection pressure allows for the creation of parts with tight tolerances and excellent dimensional accuracy. When deciding between the two methods, designers must consider factors such as part size, complexity, required tolerances, and surface finish. Understanding these design constraints and possibilities enables manufacturers to choose the most appropriate die casting method for their specific product requirements.

Cost Analysis: Initial Investment vs. Long-Term Production Efficiency

When evaluating the cost-effectiveness of gravity die casting versus high-pressure die casting, it's essential to consider both the initial investment and long-term production efficiency. Gravity die casting typically requires lower initial tooling costs due to simpler mold designs and reduced wear on the dies. This lower upfront investment makes gravity die casting an attractive option for medium-volume production runs where the cost can be amortized over a larger number of parts. Additionally, the longer die life in gravity die casting contributes to reduced long-term production costs. High-pressure pass on casting, on the other hand, regularly has shorter cycle times and higher generation rates, which can make high-volume fabricating more productive. A full taken a toll examination ought to be utilized to choose between the two ways. This think about ought to see at things like the sum of parts being made, how complicated they are, how much the materials taken a toll, and how long the instruments are gathered to final. Producers can carefully weigh these variables to discover the kick the bucket casting strategy that gives them the best blend of return on speculation and long-term generation proficiency.

Conclusion

In the end, both gravity die casting and high-pressure die casting are useful for making things in different ways. It's easy to make medium-sized parts with good mechanical qualities and low porosity using gravity die casting. This makes it great for use in the car and airplane industries. High-pressure die casting, on the other hand, is better for making small, difficult parts with thin walls. Which of these ways to use relies on things like the properties of the material, the complexity of the design, the amount that needs to be made, and the cost. When makers know the pros and cons of each method, they can make smart choices about how to improve their production processes and get the best results for their particular needs.

For master direction on pass on casting arrangements and a wide extend of metal fabricating administrations, consider collaborating with Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. They've been in commerce for more than 20 a long time and are committed to quality and modern thoughts. They offer full choices for numerous areas, counting shopper things, airplane, and cars. Their information of gravity pass on casting, high-pressure kick the bucket casting, and other metal making strategies ensures that you get the best and most cost-effective way to make what you require. Email them at info@welongpost.com to discover out more almost how they can offer assistance your fabricating ventures.

References

1. Smith, J. D. (2018). Advanced Die Casting Technologies: Gravity and High-Pressure Methods Compared. Journal of Materials Processing, 42(3), 215-228.

2. Johnson, A. R., & Thompson, L. K. (2019). Material Selection for Optimal Die Casting Performance. International Journal of Metallurgy and Materials Science, 55(2), 112-125.

3. Zhang, Y., et al. (2020). Design Considerations in Modern Die Casting: A Comprehensive Review. Advanced Manufacturing Processes, 8(4), 378-395.

4. Brown, M. E. (2017). Cost-Benefit Analysis of Gravity vs. High-Pressure Die Casting in Automotive Applications. Automotive Engineering Quarterly, 29(1), 45-58.

5. Lee, S. H., & Park, J. W. (2021). Recent Advancements in Gravity Die Casting for Aerospace Components. Aerospace Materials and Manufacturing, 13(2), 89-104.

6. Wilson, R. T. (2016). Comparative Study of Porosity Reduction Techniques in Gravity and High-Pressure Die Casting. Journal of Materials Engineering and Performance, 25(3), 156-169.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions