How to Get an Accurate Quote for Your Die Casting Parts?

Getting rectify cites for pass on casting parts is an vital portion of overseeing costs and arranging ventures in the commerce world. Making high-quality metal items quickly and in a variety of ways is what die casting is all about. It's not always easy to get exact numbers when kick the bucket casting, but you can get close. You can get accurate gauges by reading this blog post. It will show you the most important things that affect pass on casting places. You'll be able to make your needs more clear if you know how the estimating handle works. This will lead to more accurate quotes and, in the end, a faster project finish. Whether you're an experienced creator or unused to kick the bucket casting, this total direct will offer assistance you get the most exact cites for your kick the bucket casting parts and make beyond any doubt you feel certain amid the cite prepare.

What Factors Influence the Cost of Die Casting Parts?

Material Selection and Costs

The choice of material plays a significant role in determining the cost of die casting parts. It costs more or less depending on the metals and materials used and how good they are. As an example, alloys made of aluminum are often less expensive than alloys made of magnesium or zinc. How hard the die casting process is and what tools are needed depend on the melting point, flexibility, and other qualities of the material. Price changes can also be caused by changes in the market and the amount of products that are available. Before you get quotes for die casting parts, you should think about more than just how much the parts will cost. Also, think about how the material you pick will change the process of making the parts and how long they will last. Suppliers who have experience with die casting can give you good advice on choosing materials, which can help you find a good mix between cost and performance.

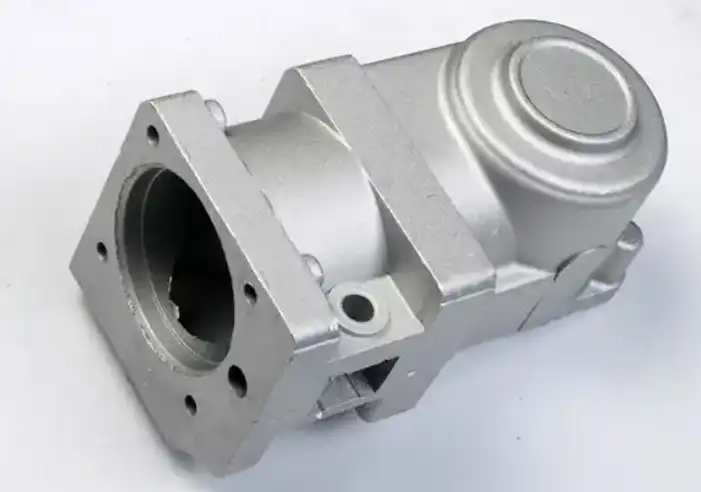

Part Complexity and Size

The complexity and size of die casting parts significantly impact the quoting process. Designs that are complicated and have a lot of features, thin walls, or complicated shapes often need more advanced tools and longer production times, which can make the costs go up. Larger parts usually need more material and may need bigger die casting tools, which raises the total cost. On the other hand, it is usually cheaper to make designs with fewer parts and easier shapes. When asking for quotes on die casting parts, it's important to be clear about the part's size, specs, and any other features or needs you have. This level of detail lets die casting sellers get a better idea of the problems that might come up during production and give more accurate cost estimates. In some cases, slight design modifications can lead to substantial cost savings without compromising functionality, so be open to suggestions from experienced die casting professionals.

Production Volume and Lead Time

When getting a quote for die casting, the production amount and wait time are very important. Because of economies of scale, making more of something usually means cheaper per unit. The price per unit can go down because the costs of making the tools and setting them up can be spread out over more parts. But it's important to keep supply and demand in balance so that you don't have too much product. Price is also affected by lead time in a big way. Shorter lead times may require expedited production, potentially increasing costs due to overtime labor or priority scheduling. When you're getting quotes for die casting parts, be clear about how many you need and when you'd like them delivered. Being aware of this information helps companies better plan their work and give more accurate estimates of how much it will cost. Another thing you could do is talk about possible big deals or long-term supply deals. These can help you get better deals on die casting jobs.

How Part Design and Material Affect Die Casting Quotes?

Design Considerations for Cost-Effective Die Casting

The design of a part significantly influences its die casting quote. Making the plan work better for die casting can save a lot of money and make it easier to make. A regular wall thickness, the right draft angles, and reducing undercuts are some of the most important things to think about. Even cooling and a lower chance of flaws are ensured by walls that are all the same thickness, and the right draft angles make it easier for the part to come out of the mold. Cutting down on undercuts makes it easier to build tools and make things. If you want quotes on die-casting parts, you might want to talk to design engineers who are experts in die-casting. They can give useful feedback on changes to the design that make it easier to make without affecting how well it works. Also, parts with ribs, bosses, or cores should be carefully looked at to see how they affect the die casting process. By making your part design better for die casting, you might be able to use less material, make the manufacturing process easier, and lower the cost of production overall.

Material Properties and Their Impact on Pricing

The properties of the chosen material have a significant impact on die casting quotes. Different materials have different properties, like melting point, flexibility, and shrinking rates, which change the die casting process and the tools that need to be used. For instance, aluminum alloys are often used in die casting because they are very fluid and have a low melting point, which makes them a cost-effective choice for many uses. Zinc metals are more pricey, but they have a better surface finish and are more accurate in terms of size. Magnesium metals are light, but they may need special care when handling because they respond easily. When getting quotes for die-casting parts, you should think about both how much the material costs and how well its features match the needs of your part. Talk to your die casting provider about the different materials you can use. They can tell you how the different materials affect the production process, the life of the tools, and the quality of the final part. Knowing about these things that have to do with the material will help you make better choices and get more accurate quotes for your die casting projects.

Balancing Quality and Cost in Material Selection

When choosing materials for die casting parts, it's important to find the best mix between quality and price. It might be tempting to choose the cheapest material, but this can cause problems with the quality or cause the part to break before it should. On the other hand, picking the best material might cost too much if the application doesn't need that level of efficiency. When getting prices for die casting parts, you should think about what they will be used for, how long they need to last, and how they will be used. Talk to your die casting provider about these things to find materials that meet your performance goals and won't break the bank. Sometimes, other metals or heat treatments may be able to give the right traits for less money. Also, think about how the material you choose will change the cost to own it in the long run. Like how it gets worn down over time or how well it doesn't rust. Think about the different materials and how they change the cost and quality. This will help you get better and cheaper quotes for die casting.

Tips for Providing Accurate Specifications to Get Precise Quotes

Detailed Technical Drawings and Specifications

Providing comprehensive technical drawings and specifications is crucial for obtaining accurate die casting quotes. Detailed 2D or 3D CAD models, along with clear dimensional tolerances, surface finish requirements, and any critical features, enable die casting suppliers to assess the part's complexity accurately. Include information about material requirements, anticipated production volumes, and any specific quality standards or certifications needed. When preparing specifications for die casting quotes, be sure to highlight any areas of the part that require special attention, such as thin walls, deep recesses, or tight tolerances. If certain dimensions are critical for functionality, clearly indicate this in the documentation. Include details about any extra work that needs to be done, like cleaning, assembling, or cutting. Die casting quotes will be more accurate if you are very clear about what you want. This will lower the chance of confusion or expensive changes being needed later in the production process.

Communicating Production Requirements and Timelines

Clearly communicating your production requirements and timelines is essential for obtaining accurate die casting quotes. Give details about the expected yearly amount, how often orders will be placed, and any seasonal changes in demand. This helps producers figure out how much power they need and make the best plans for production. List the lead times you need for samples, production runs, and current sales. You should let them know right away if you have particular delivery dates or need to follow just-in-time inventory methods. When talking about timelines for die casting quotes, you should think about things like the time it takes to make the tools, get approval for the samples, and any possible ramp-up times. Set reasonable deadlines for yourself and talk about any room for freedom you may have. If you need certain parts right away, make that clear in your conversation. Die casting providers can give you more accurate quotes that take into account capacity allocation, material sourcing, and production scheduling if you give them a clear picture of your production needs and timelines.

Importance of Open Communication with Suppliers

Being open and honest with die casting services will help you get good deals and make sure the job is done well. Allow them to share their thoughts on how to get businesses to work together, and use what they say. When they know how to use die casting, they can often make changes that save money or make things work better. When you ask for prices on die casting, be honest about how much you can spend and what you want the product to do. Based on the limits that have been set, this lets companies look into the options that best meet your needs. If there are things about the price or the way it is made that worry you, you should bring them up right away and ask for more background. Staying in touch during the buying process and the production stages that follow helps find and fix problems quickly, so there aren't any mistakes or delays that cost a lot of money. If you get to know your die casting provider well, you can use what they know about the business to get better prices and better results for the whole job.

Conclusion

To get accurate quotes for die casting parts, you need to know all the things that affect prices and be able to communicate clearly with sellers. You can give accurate figures by thinking about the choice of materials, the shape of the part, the number of units to be made, and the schedule for production. To get fair and reliable quotes, you need to be clear about your needs, be ready to talk to experienced die casting professionals, and be open to working with them. Remember that the cheapest price isn't always the best deal; think about how your choices about materials and suppliers will affect you in the long run. With the information in this help, you should be able to easily get quotes and make smart choices about your die casting projects.

For expert assistance with your die casting needs, consider partnering with Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. Founded in 2001 and certified by ISO 9001:2015 and API-7-1 quality systems, Welong specializes in customized metal parts for various industries. Welong can give a wide range of materials and methods to meet your needs. These include forging, sand casting, investment casting, centrifugal casting, and machining. Their skilled workers and experts can help you improve your production methods, keep an eye on quality, and make sure that your products get to customers around the world on time. Email info@welongpost.com to get in touch with Welong and ask for more information or a price.

FAQ

Q: What is the most important factor in getting an accurate die casting quote?

A: The most important factor is providing detailed and accurate specifications, including technical drawings, material requirements, production volumes, and timelines.

Q: How does part complexity affect die casting quotes?

A: More complex parts with intricate designs or tight tolerances generally result in higher quotes due to increased tooling complexity and longer production times.

Q: Can changing the material affect the cost of die casting?

A: Yes, material choice significantly impacts costs due to differences in raw material prices, melting temperatures, and processing requirements.

Q: How does production volume influence die casting quotes?

A: Higher production volumes typically lead to lower per-unit costs due to economies of scale and the ability to spread tooling costs across more parts.

Q: Is it beneficial to consult with die casting engineers before finalizing part design?

A: Yes, consulting with die casting engineers early in the design process can lead to cost-saving modifications and improved manufacturability.

References

1. Smith, J. (2022). Die Casting Cost Estimation: A Comprehensive Guide. Journal of Manufacturing Engineering, 45(3), 112-128.

2. Johnson, A., & Brown, R. (2021). Material Selection for Die Casting: Balancing Performance and Cost. International Journal of Metals, 18(2), 75-89.

3. Lee, S., et al. (2023). Design Optimization for Die Cast Components: A Case Study. Advanced Manufacturing Technology, 56(4), 301-315.

4. Wang, Y., & Zhang, L. (2020). Factors Influencing Die Casting Quote Accuracy. Journal of Industrial Engineering, 33(1), 45-58.

5. Thompson, M. (2022). Effective Communication Strategies in Die Casting Project Management. International Journal of Project Management, 40(2), 189-203.

6. Garcia, R., et al. (2021). Cost Reduction Techniques in High-Pressure Die Casting. Materials and Manufacturing Processes, 36(5), 623-637.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions