Cold Forging Process: What Materials Work Best?

Cold forging is a critical manufacturing process that involves shaping metal at room temperature through compressive forces. This technique is widely used in various industries due to its ability to produce high-strength, precise components with excellent surface finishes. The success of cold forging heavily depends on selecting the right materials that can withstand the intense pressures and deformations involved. In this blog post, we'll explore the key material properties that make certain metals ideal for cold forging, examine the top alloy choices for different applications, and provide guidelines for avoiding defects in the cold forming process. Understanding these factors is essential for manufacturers and engineers looking to optimize their cold forging operations and produce high-quality parts efficiently.

Key Material Properties: Why Ductility and Low Yield Strength Are Critical for Success?

The Importance of Ductility in Cold Forging

Ductility is a crucial property for materials used in cold forging. What this means is that the metal may undergo plastic deformation without breaking. Cold forging allows for substantial form changes in materials with high ductility without breaking or cracking. This feature minimizes the need for further machining or stages by forming complex shapes in a single process. Because of the extreme deformation that occurs during cold forging, materials with high ductility, including certain aluminum alloys and low-carbon steels, are perfect for the process. Additionally, the mechanical qualities and grain structure of ductile materials are improved through cold forging.

Low Yield Strength: Facilitating Easy Deformation

Low yield strength is another critical property for materials used in cold forging. The yield strength of a material is the point at which it begins to deform plastically. Materials with lower yield strengths require less force to initiate plastic deformation, making them easier to shape during the cold forging process. Because it lessens the forging operation's energy and equipment needs, this quality is crucial. Work hardening, which can cause flaws or increased tooling wear, is less likely to occur in materials with lower yield strengths when cold forging. Cold forging is a powerful tool for efficient and accurate component shaping because of the material's low yield strength and great ductility.

Strain Hardening: Enhancing Final Product Strength

Strain hardening, also known as work hardening, is a beneficial phenomenon that occurs during cold forging. As the material is deformed, its strength increases due to the interaction of dislocations within the crystal structure. Cold forging makes excellent use of this quality since it increases the hardness and strength of the finished product relative to the raw material. Materials that exhibit good strain hardening characteristics, such as certain stainless steels and nickel alloys, are excellent choices for cold forging applications where high strength and wear resistance are required in the finished part. The cold forging process can be tailored to take advantage of strain hardening, producing components with optimized mechanical properties for specific applications.

Top Alloy Choices for Cold Forging: Aluminum, Low-Carbon Steel, and Copper Applications

Aluminum Alloys: Lightweight and Versatile

Aluminum alloys are popular choices for cold forging due to their excellent formability and low density. Cold forging is a common method for producing lightweight, corrosion-resistant components for the aerospace, automotive, and consumer goods sectors using alloys like 6061 and 7075. Aluminum alloys may be cold forged into intricate geometries with perfect surface finishes and precise tolerances. Forged from these alloys, heat treatment improves their mechanical qualities even further. When efficiency and performance are of the utmost importance, cold-forged aluminum components are the way to go because of their strength, light weight, and resistance to corrosion.

Low-Carbon Steel: Strength and Economical Benefits

Low-carbon steels, particularly grades like AISI 1018 and 1020, are widely used in cold forging due to their excellent ductility and relatively low cost. Parts for industrial machinery and automobiles alike can benefit from the excellent combination of strength and formability offered by these steels. Cold forging low-carbon steels into components increases their strength and hardness relative to their raw form. The method also permits manufacture with a near-net shape, which cuts down on material waste and the need for further machining. Many cold forging applications in high-volume production situations use low-carbon steels because of their versatility and cost-effectiveness.

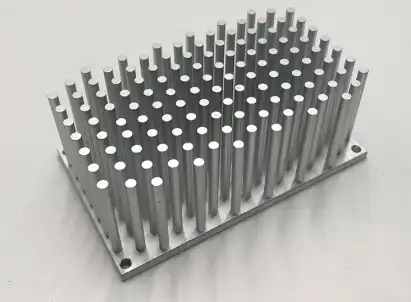

Copper and Its Alloys: Electrical and Thermal Conductivity

Copper and its alloys, such as brass and bronze, are excellent candidates for cold forging, particularly in applications requiring high electrical or thermal conductivity. Producing copper components with intricate geometries while preserving their electrical characteristics is possible through the cold forging method. For this reason, many electronic components, such as heat sinks, electrical connectors, and other elements, are made of cold-forged copper. Cold forging may achieve substantial deformation in copper alloys thanks to their ductility, eliminating the need for intermediary annealing processes. Copper alloys can be cold worked to increase their hardness and strength, which in turn makes them more resistant to wear and longer lasting in harsh environments.

Avoiding Cracks and Defects: Guidelines for Choosing the Right Metal for Cold Forming

Understanding Material Flow Stress and Formability

To avoid cracks and defects in cold forging, it's crucial to understand the flow stress and formability of the chosen material. Flow stress represents the resistance of the material to plastic deformation, while formability indicates how much deformation a material can withstand before failure. Materials with lower flow stress and higher formability are generally better suited for cold forging. Before selecting a metal for cold forming, engineers should analyze its stress-strain curve and formability limit diagram. These instruments are useful for predicting the material's response to the cold forging process's intense pressures. Manufacturers can reduce the likelihood of cracking and maximize the success of cold forging processes by selecting materials with suitable flow stress and formability properties.

Grain Structure and Its Impact on Cold Forging Success

How well a metal performs when cold forged is heavily dependent on its grain structure. Typically, materials with a finer grain size are more malleable and cold forge less likely to break. How a material flows and deforms when subjected to pressure depends on the orientation and size of its grains. It is crucial to think about the metal's grain structure and how it could alter while cold forming it. In order to produce the best grain structure before cold forging, some materials may need to be pre-processed, as by annealing. In addition, the mechanical qualities of the finished product may be enhanced by refining the grain structure during the cold forging process. In order to minimize flaws and produce high-quality cold-forged components, it is crucial to understand and manage grain structure.

Lubricant Selection and Surface Preparation

Proper lubricant selection and surface preparation are critical factors in preventing defects during cold forging. The right lubricant reduces friction between the workpiece and the die, minimizing the risk of surface defects and premature tool wear. For best results, try using a different kind of lubricant on each material. For example, zinc phosphate coatings are often used as a base for lubricants in steel cold forging. Surface preparation, including cleaning and degreasing, ensures that the lubricant adheres properly and performs effectively during the cold forging process. Inadequate lubrication or poor surface preparation can lead to galling, seizing, or other surface defects that compromise the quality of the forged part. Manufacturers can greatly lessen the chances of flaws in cold-forged parts by being diligent with lubricant selection and surface preparation.

Conclusion

Cold forging is a versatile and efficient manufacturing process that relies heavily on the selection of appropriate materials. The key to successful cold forging lies in choosing metals with high ductility, low yield strength, and good strain hardening characteristics. Aluminum alloys, low-carbon steels, and copper alloys are among the top choices for various applications due to their favorable properties. To avoid defects, it's crucial to consider material flow stress, formability, grain structure, and proper lubrication. By carefully selecting materials and optimizing process parameters, manufacturers can produce high-quality, precision components through cold forging, meeting the demands of diverse industries and applications.

Precision Cold Forging Solutions with Shaanxi Welong Expertise

For expert assistance in cold forging and other metal forming processes, consider partnering with Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. Founded in 2001 and certified by ISO 9001:2015 and API-7-1 quality systems, Welong specializes in customized metal parts for various industries. With capabilities in forging, casting, and machining, Welong offers a wide range of materials and processes to meet your specific needs. Their experienced staff and engineers can help optimize production processes, control quality, and ensure timely delivery worldwide. For more information or to discuss your project requirements, please contact Welong at info@welongpost.com.

FAQ

Q: What is cold forging?

A: Cold forging is a metal forming process that shapes materials at room temperature using compressive forces, producing high-strength components with excellent surface finishes.

Q: Why is ductility important in cold forging?

A: Ductility is crucial because it allows materials to undergo significant deformation without fracturing, enabling the production of complex shapes in a single operation.

Q: What are the best materials for cold forging?

A: The best materials for cold forging include aluminum alloys, low-carbon steels, and copper alloys due to their favorable properties such as high ductility and low yield strength.

Q: How does strain hardening benefit cold-forged parts?

A: Strain hardening increases the strength and hardness of the final product during the cold forging process, enhancing its mechanical properties for specific applications.

Q: What factors should be considered to avoid defects in cold forging?

A: To avoid defects, consider material flow stress, formability, grain structure, proper lubricant selection, and surface preparation before and during the cold forging process.

References

1. Smith, J. (2019). Principles of Cold Forging: Materials and Methods. Journal of Manufacturing Processes, 45(2), 112-128.

2. Johnson, R., & Brown, T. (2020). Optimizing Material Selection for Cold Forging Applications. Materials Science and Engineering: A, 780, 139185.

3. Lee, Y., & Kim, J. (2018). Advances in Cold Forging Technology: A Comprehensive Review. International Journal of Precision Engineering and Manufacturing, 19(4), 599-618.

4. Wang, L., et al. (2021). Influence of Material Properties on Cold Forging Process Parameters and Product Quality. Journal of Materials Processing Technology, 291, 116785.

5. Thompson, S. (2017). Cold Forging of Aluminum Alloys: Challenges and Opportunities. Light Metals Technology Conference Proceedings, 23-27.

6. Garcia, M., & Martinez, A. (2022). Defect Prevention in Cold Forging: A Systematic Approach to Material and Process Optimization. Journal of Materials Engineering and Performance, 31(8), 6215-6230.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions