Residual stress management represents one of the most critical challenges in modern manufacturing, particularly affecting the dimensional stability, fatigue resistance, and overall performance of cast and forged components. These internal stresses develop during cooling processes, mechanical working, and thermal treatments, creating potential failure points that can compromise product integrity. Understanding effective elimination techniques becomes essential for manufacturers seeking to produce high-quality components that meet stringent international standards. Through systematic application of proven stress relief methods, manufacturers can significantly enhance component reliability while reducing costly quality issues downstream.

Understanding Internal Stress Formation in Manufacturing Processes

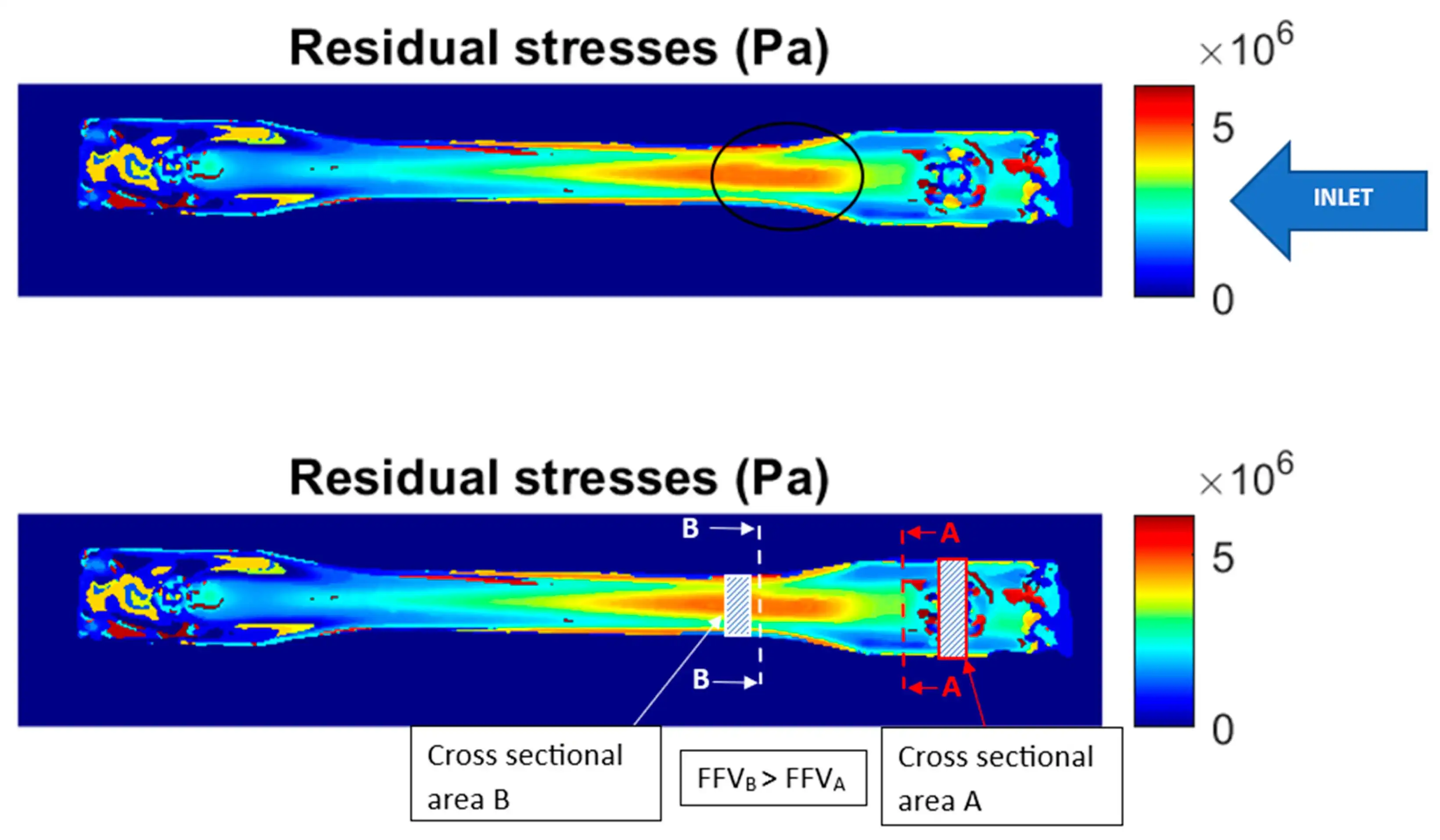

Internal stress formation occurs through multiple mechanisms during casting and forging operations. Thermal gradients create the most common stress patterns as different sections of components cool at varying rates. Rapid cooling generates tensile stresses on surfaces while compressive stresses develop in core regions. This differential cooling creates stress concentrations that persist long after manufacturing completion. Mechanical working processes introduce additional complexity through plastic deformation patterns. Die forging operations create stress distribution variations based on material flow directions and tooling contact pressures. Understanding these formation mechanisms allows engineers to predict stress patterns and implement targeted elimination strategies. Microstructure changes during processing contribute significantly to internal stress development. Phase transformations, grain boundary modifications, and precipitation reactions all influence final stress states. These metallurgical factors interact with thermal and mechanical influences to create complex stress profiles requiring sophisticated analysis techniques.

Advanced Stress Analysis and Measurement Techniques

Residual Stress measurement relies heavily on X-ray diffraction technology for precise stress analysis. This non-destructive technique measures lattice strain variations to determine stress magnitudes and directions. X-ray diffraction provides accurate surface stress measurements essential for quality control validation. Finite element analysis enables comprehensive stress distribution modeling throughout component geometries. These computational tools predict stress patterns before manufacturing, allowing proactive design modifications. Advanced simulation capabilities help optimize heat treatment cycles and cooling strategies for improved stress management. Strain gauge measurements offer real-time stress monitoring during manufacturing processes. These instruments track stress development patterns, enabling process adjustments that minimize unwanted stress formation. Combined measurement approaches provide comprehensive stress characterization necessary for effective elimination planning.

Thermal Stress Relief Methods and Applications

Thermal stress relief represents the most widely implemented stress elimination technique across industrial applications. Controlled heating cycles reduce yield strength temporarily, allowing stress relaxation through limited plastic deformation. Temperature selection depends on material composition and desired stress reduction levels. Annealing treatments provide complete stress elimination through recrystallization processes. These high-temperature treatments reset grain structures while eliminating virtually all internal stresses. Annealing works particularly well for components requiring maximum dimensional stability over extended service periods. Tempering operations combine stress relief with mechanical property optimization. These treatments reduce brittleness while relieving stresses, making them ideal for high-strength applications. Tempering parameters require careful optimization to balance stress relief with performance requirements. Stress relief furnace design significantly impacts treatment effectiveness. Uniform heating ensures consistent stress reduction throughout component volumes. Advanced furnace controls maintain precise temperature profiles essential for repeatable stress relief results.

Mechanical Stress Elimination Approaches

Residual Stress relief utilizes controlled mechanical energy to promote stress relaxation without heating. This technique applies low-amplitude vibrations at specific frequencies to encourage stress redistribution. Vibration methods work effectively for large components where thermal treatments prove impractical. Shot peening introduces beneficial compressive stresses while relieving existing tensile stresses. High-velocity impacts create surface compression that counteracts harmful tensile stress concentrations. Shot peening parameters require optimization based on component geometry and material properties. Controlled plastic deformation techniques strategically exceed yield points in specific regions to relieve stress concentrations. These methods require precise force application to avoid component damage while achieving desired stress reduction. Deformation approaches work well for components with localized stress problems. Machining stress relief involves removing stressed material layers to eliminate stress concentrations. Strategic material removal reduces stress magnitudes while maintaining component functionality. Machining approaches prove effective when combined with other stress relief techniques.

Industry-Specific Applications and Quality Standards

Aerospace applications demand exceptional stress control due to safety-critical performance requirements. Components experience extreme temperature variations and cyclic loading that amplify stress-related failures. Aerospace stress relief protocols follow rigorous qualification procedures, ensuring consistent results. Automotive manufacturing emphasizes cost-effective stress relief methods compatible with high-volume production. Automated stress relief systems enable consistent treatment of large component quantities. Automotive applications balance stress relief effectiveness with manufacturing efficiency requirements. Oil and gas drilling equipment operates under severe conditions where stress-related failures create significant safety risks. Downhole components require complete stress elimination to withstand extreme pressures and temperatures. Specialized stress relief procedures address unique challenges in energy sector applications. Medical device manufacturing requires precise stress control to ensure biocompatibility and performance reliability. Implantable components must demonstrate exceptional fatigue resistance achieved through comprehensive stress elimination. Medical applications follow strict validation protocols confirming stress relief effectiveness.

Process Optimization and Quality Control Implementation

Residual Stressrelief process optimization requires systematic evaluation of treatment parameters against component performance requirements. Statistical process control methods track stress relief consistency across production batches. Data-driven optimization improves treatment effectiveness while reducing processing costs. ISO 9001:2015 compliance demands documented stress relief procedures with verifiable results. Quality management systems ensure consistent application of proven stress relief techniques. Certification requirements drive implementation of robust stress relief protocols. Process validation involves comprehensive testing to confirm stress relief effectiveness under actual service conditions. Fatigue testing, dimensional stability measurements, and fracture mechanics analysis validate treatment success. Validation protocols provide confidence in the stress relief process's reliability. Documentation requirements include detailed records of stress relief parameters, measurement results, and quality verification data. Traceability systems link individual components to specific stress relief treatments. Complete documentation supports quality assurance and continuous improvement initiatives.

Troubleshooting Common Stress Relief Challenges

Incomplete stress relief often results from inadequate temperature control or insufficient treatment duration. Monitoring systems track actual temperatures throughout component volumes to ensure uniform heating. Extended treatment times may be necessary for large or complex geometries. Distortion during stress relief indicates excessive heating rates or inadequate fixturing. Controlled heating and cooling rates minimize distortion while maintaining stress relief effectiveness. Proper component support prevents gravity-induced deformation during elevated temperature exposure. Stress corrosion cracking risks increase when stress relief proves incomplete. Comprehensive stress elimination reduces susceptibility to environmental cracking mechanisms. Post-treatment stress verification confirms adequate stress reduction for service environments. Surface quality degradation during thermal treatments requires careful atmosphere control and temperature management. Protective atmospheres prevent oxidation while maintaining surface finish requirements. Vacuum treatments eliminate contamination risks for critical applications.

Conclusion

Residual Stress relief management represents a cornerstone of modern manufacturing quality, directly impacting component performance, reliability, and service life. Understanding formation mechanisms, implementing appropriate elimination techniques, and maintaining rigorous quality control ensure optimal results across diverse industrial applications. Success requires combining theoretical knowledge with practical experience, supported by comprehensive measurement and validation protocols. As manufacturing requirements continue evolving toward higher precision and reliability standards, mastering stress relief techniques becomes increasingly critical for competitive advantage. Investment in proven stress relief capabilities delivers measurable returns through reduced warranty claims, improved customer satisfaction, and enhanced reputation for quality excellence.

Partner with Welong for Expert Stress Relief Manufacturing Solutions

Welong delivers comprehensive stress relief manufacturing services backed by two decades of experience serving global industrial clients. Our ISO 9001:2015 certified facility employs advanced thermal treatment equipment and precision measurement systems to ensure optimal stress elimination results. Working directly with our engineering team, you'll receive customized solutions that address your specific stress relief requirements while maintaining strict quality standards. Contact us at info@welongpost.com to discuss how our residual stress elimination expertise can enhance your component reliability and manufacturing success.

References

1. Withers, P.J., and Bhadeshia, H.K.D.H. (2001). "Residual Stress Part 1 - Measurement Techniques." Materials Science and Technology, 17(4), 355-365.

2. Lu, J. (1996). "Handbook of Measurement of Residual Stresses." Society for Experimental Mechanics, Fairmont Press, Lilburn, GA.

3. Totten, G.E., Howes, M.A.H., and Inoue, T. (2002). "Handbook of Residual Stress and Deformation of Steel." ASM International, Materials Park, Ohio.

4. James, M.N., and Lu, J. (1996). "Residual Stress and Its Effects on Fatigue and Fracture." Engineering Materials Advisory Services Ltd, Cradley Heath, UK.

5. Schajer, G.S. (2013). "Practical Residual Stress Measurement Methods." John Wiley & Sons, Chichester, UK.

6. Webster, G.A., and Ezeilo, A.N. (2001). "Residual Stress Distributions and Their Influence on Fatigue Lifetimes." International Journal of Fatigue, 23, 375-383.