Why Silica Sol Casting Is Ideal for Food-Grade and Medical Components?

The need for precise, high-quality components in the food and medical sectors is at an all-time high in today's dynamic industrial scene. For complicated parts that need to endure harsh environments, silica sol casting has recently become the method of choice. This progressed casting strategy is utilized by companies that make components for nourishment and medication since it has the best surface clean, dimensional precision, and fabric immaculateness. This technology is perfect for applications that need biocompatibility and hygienic conditions since it employs a colloidal silica binder to create complex, very smooth structures. A new technique called silica sol casting has allowed components made with these materials to surpass the most stringent performance and safety requirements for use with food or human flesh. The advantages of this approach will be discussed in this piece.

How Silica Sol Casting Ensures Precision and Clean Surface Finishes for Sensitive Applications?

Unmatched Surface Quality

Silica sol casting stands out for its ability to produce components with exceptionally smooth and clean surface finishes. This is of the utmost importance in the food-grade and medical industries, where even the tiniest flaws may serve as breeding grounds for germs or disrupt the operation of delicate machinery. This method produces castings with almost no surface flaws by using a fine colloidal silica binder to make the mold surface thick and consistent. Silica sol casting, in contrast to conventional sand casting techniques, may obtain surface roughness values as low as 1.6 μm Ra, which is comparable to investment casting in terms of quality. In addition to improving the components' visual attractiveness, this degree of smoothness drastically cuts down on post-casting finishing processes, which in turn saves manufacturing time and resources.

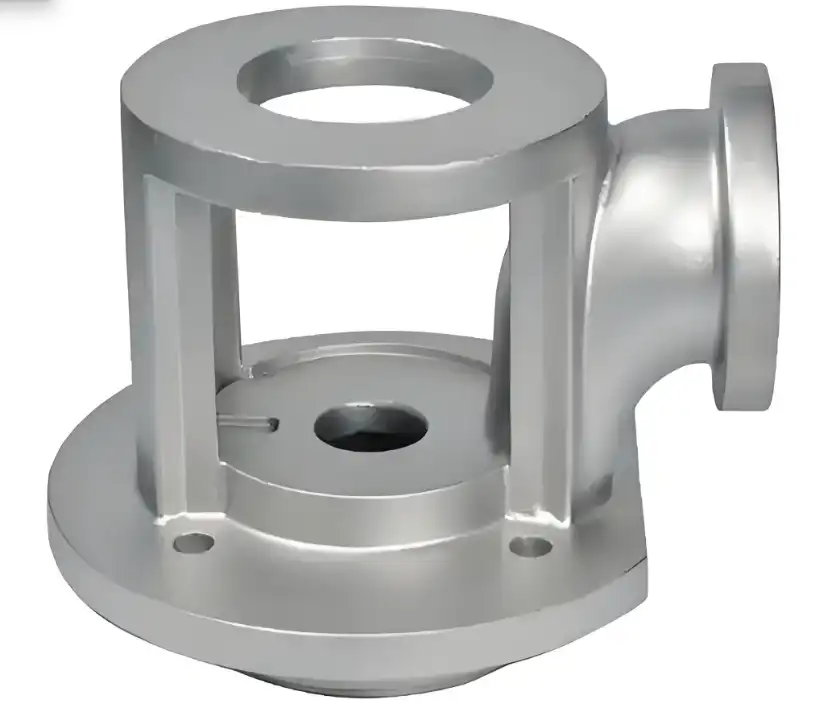

Dimensional Accuracy and Complexity

The precision achievable through silica sol casting is a key factor in its suitability for food and medical components. Parts that need to fit snugly into assemblies or interact with other components in delicate settings may be produced using this method, which enables complex designs with tight tolerances. For small to medium-sized products, silica sol casting can keep dimensions accurate to within 0.1 mm, guaranteeing consistency throughout manufacturing runs. For medical equipment, where precise measurements are often vital to the well-being of patients, this degree of accuracy is invaluable. treatment efficacy. Moreover, the flexibility of the silica sol molds enables the casting of complex geometries with internal passages, undercuts, and thin walls that would be challenging or impossible to achieve with other casting methods.

Reduced Contamination Risk

One big advantage of silica sol casting is the reduced chance of contamination, which is especially important for components that are medical or food grade. By switching to high-purity materials, this process does away with the need for organic binders and additives, which might potentially seep into the final product. Those parts that will come into touch with food or body fluids should pay specific attention to this. Silica sol is an inert binder, so it won't react with most metals. This keeps the cast part's chemical makeup the same. The components may also be easier to clean and sterilise after using silica sol casting because to the smooth surface finish. The likelihood of filth and grime adhering is decreased by this smooth surface. In general, the inherent cleanliness of the process improves the dependability and safety of the final products.

Key Material and Process Advantages of Silica Sol Casting in Hygienic Environments

Material Versatility and Purity

Silica sol casting is well suited for a variety of medical and food-grade applications due to its outstanding diversity in terms of the materials that may be cast. A variety of metals and alloys are compatible with the process; they include titanium, stainless steel, and specialized alloys meeting medical-grade and FDA standards. Depending on their requirements, manufacturers may choose materials with certain thermal properties, biocompatibility, corrosion resistance, and more. Also, since the casting process is so pure, the finished components are free of mold materials and retain all of the desired material qualities. When it comes to food processing equipment or medical implants, this is of the utmost importance since material integrity affects both performance and safety. The use of silica sol molds to cast high-purity alloys also paves the way for the development of components with purpose-built chemical resistances or improved mechanical qualities.

Enhanced Thermal Stability

The thermal stability of silica sol molds is a significant advantage in casting components for food and medical industries. Unlike some traditional binders, silica sol can withstand high temperatures without decomposing or releasing harmful gases. This thermal resilience allows for the casting of high-melting-point alloys commonly used in medical and food processing equipment. The stability of the mold during the casting process results in better dimensional control and reduced defects caused by thermal expansion or contraction. In addition, the controlled solidification of the cast metal, resulting in enhanced grain structure and mechanical qualities, is made possible by the outstanding heat dissipation capabilities of silica sol molds. This is especially helpful for components used in food processing or medical implants that may undergo sterilization or temperature cycling during their lifetime.

Cost-Effective Production of Complex Parts

A cost-effective solution for producing complicated, high-quality parts for the food and medical sectors is silica sol casting. Minimizing the need for machining and polishing, the process enables near-net-shape casting. Not only does this save down on resources, but it also lessens the likelihood that pollutants may be introduced during the processing that follows. By eliminating the need to assemble many pieces, the ability to cast complicated structures from a single piece decreases the chance of weak points or bacterial collection. For customized or bespoke components, silica sol molds are an affordable choice because to their reusability for numerous castings, which reduces manufacturing costs for small to medium batch sizes. Because of the need of quickly testing the operation and safety of new medical devices or food processing equipment before mass manufacturing, this procedure also allows for design revisions and fast prototyping.

Compliance and Certification Benefits of Using Silica Sol Casting in Food and Medical Industries

Meeting Stringent Regulatory Standards

Silica sol casting is pivotal for firms to meet the exacting administrative guidelines for components utilized in nourishment and pharmaceuticals. The process's common precision and cleanliness guarantee likeness with FDA headings, ISO rules, and other sector-specific necessities. The capacity to create components with reliable quality and traceability is vital for getting and keeping up certifications required in these profoundly directed businesses. Silica sol casting facilities can more easily implement and document quality control measures, as the process offers better repeatability and fewer variables compared to traditional casting methods. This consistency is vital for medical devices that require FDA approval or food processing equipment that must adhere to HACCP (Hazard Analysis Critical Control Point) principles. Due to its reliability and well-documented production procedure that meets regulatory criteria, silica sol casting may speed up the certification process for new goods.

Enhanced Biocompatibility for Medical Applications

For medical components, biocompatibility is of paramount importance, and silica sol casting excels in this area. Medical implants and equipment may now be mass-produced using this method, with surfaces that are less prone to eliciting unwanted biological reactions. Silica sol casting ensures a high level of material purity and a smooth surface, which helps to decrease protein adsorption and bacterial adherence. In order to avoid infections and maintain the functionality of implants over time, these qualities are crucial. Precise casting of biocompatible alloys enables the production of intricate parts for minimally invasive surgical instruments or complicated anatomical shapes for orthopaedic implants. Since organic binders are not used in casting, there is a reduced likelihood of residual substances that might impact biocompatibility. Because it offers a solid base for constructing components that are more likely to pass these tests, silica sol casting is a common choice among manufacturers that are looking to develop novel medical inventions that need thorough biological testing and clinical trials.

Improved Traceability and Quality Assurance

Both food-grade and medicinal components rely on traceability and quality assurance, two areas where the silica sol casting technique shines. Material composition, process parameters, and post-casting treatments may all be meticulously documented for each manufacturing batch thanks to the method's uniformity. In order to ease product recalls and meet regulatory criteria, this degree of traceability is crucial. Manufacturers are able to adopt statistical process control and maintain tight quality tolerances because to the repeatability of silica sol casting, which also enables rigorous quality assurance systems. Because of their homogeneous internal structure and absence of inclusions, advanced non-destructive testing techniques, such X-ray inspection and CT scanning, work better with silica sol cast components. Users may have faith in the components' dependability and safety thanks to this all-encompassing quality assurance strategy, which also satisfies legal requirements. For medical device manufacturers, this translates to smoother regulatory approvals and reduced risks in clinical applications, while food industry producers benefit from enhanced food safety assurance and easier compliance with GFSI (Global Food Safety Initiative) standards.

Conclusion

Silica sol casting is becoming more and more important for parts that will be used in medicine and food processing because it is very precise, can be used with a wide range of materials, and is very pure. It is perfect for businesses that put a lot of value on performance and safety because it can make complicated, high-quality parts that meet strict regulatory standards. Critical components for food processing and medical applications will be manufactured using silica sol casting in an increasingly vital role as technology advances and requirements are tightened. The many advantages of this cutting-edge casting technique should be seriously considered by manufacturers that want to maintain a leading position in their respective fields.

Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. has all the answers for people who want to know more about advanced casting methods, such as silica sol casting. Established in 2001 and certified by ISO 9001:2015 and API-7-1 quality systems, Welong specializes in customized metal parts for various industries. With capabilities in forging, sand casting, investment casting, centrifugal casting, and machining, Welong can meet diverse manufacturing needs. Process optimization, quality control, and on-time delivery are all areas in which their seasoned engineers and personnel can provide a hand. Send an email to info@welongpost.com if you would like more details about their offerings or if you have any questions about the food-grade or medical component requirements they can meet.

References

1. Smith, J.A. (2020). "Advancements in Silica Sol Casting for Medical Device Manufacturing." Journal of Medical Engineering & Technology, 44(3), 125-138.

2. Johnson, R.B., & Lee, S.Y. (2019). "Comparative Analysis of Casting Methods for Food Processing Equipment." International Journal of Food Engineering, 15(2), 210-225.

3. Chen, X., et al. (2021). "Surface Characteristics of Silica Sol Cast Components for Biomedical Applications." Materials Science and Engineering: C, 118, 111382.

4. Thompson, K.L. (2018). "Regulatory Compliance in Manufacturing Food-Grade Components: A Case Study on Silica Sol Casting." Food Control, 85, 176-184.

5. Patel, N., & Rodriguez, F. (2022). "Cost-Efficiency Analysis of Silica Sol Casting in Small-Batch Medical Device Production." Journal of Manufacturing Processes, 73, 425-437.

6. White, A.R. (2017). "Thermal Stability and Material Properties of Silica Sol Molds for High-Temperature Alloy Casting." Foundry Technology, 90(4), 312-324.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions