What inspection standards are used for forged shafts

Forged shafts are basic components in different businesses, from cars to aviation, and ensuring their quality and unwavering quality is vital. To keep up the most elevated benchmarks of security and execution, a comprehensive set of review measures is utilized throughout the fabricating prepare. These guidelines include different angles of the manufactured shaft, including dimensional precision, fabric properties, surface wrap-up, and inside keenness. The review handle regularly includes a combination of visual examinations, non-destructive testing strategies, and advanced estimation procedures. By following these thorough review measures, producers can ensure that produced shafts meet the rigid requirements of their planning applications, giving clients certainty in the product's strength and execution. This article will dig into the different assessment guidelines utilized for manufactured shafts, investigating the strategies and advances utilized to guarantee the highest quality in these pivotal components.

What are the key dimensional inspection methods for forged shafts?

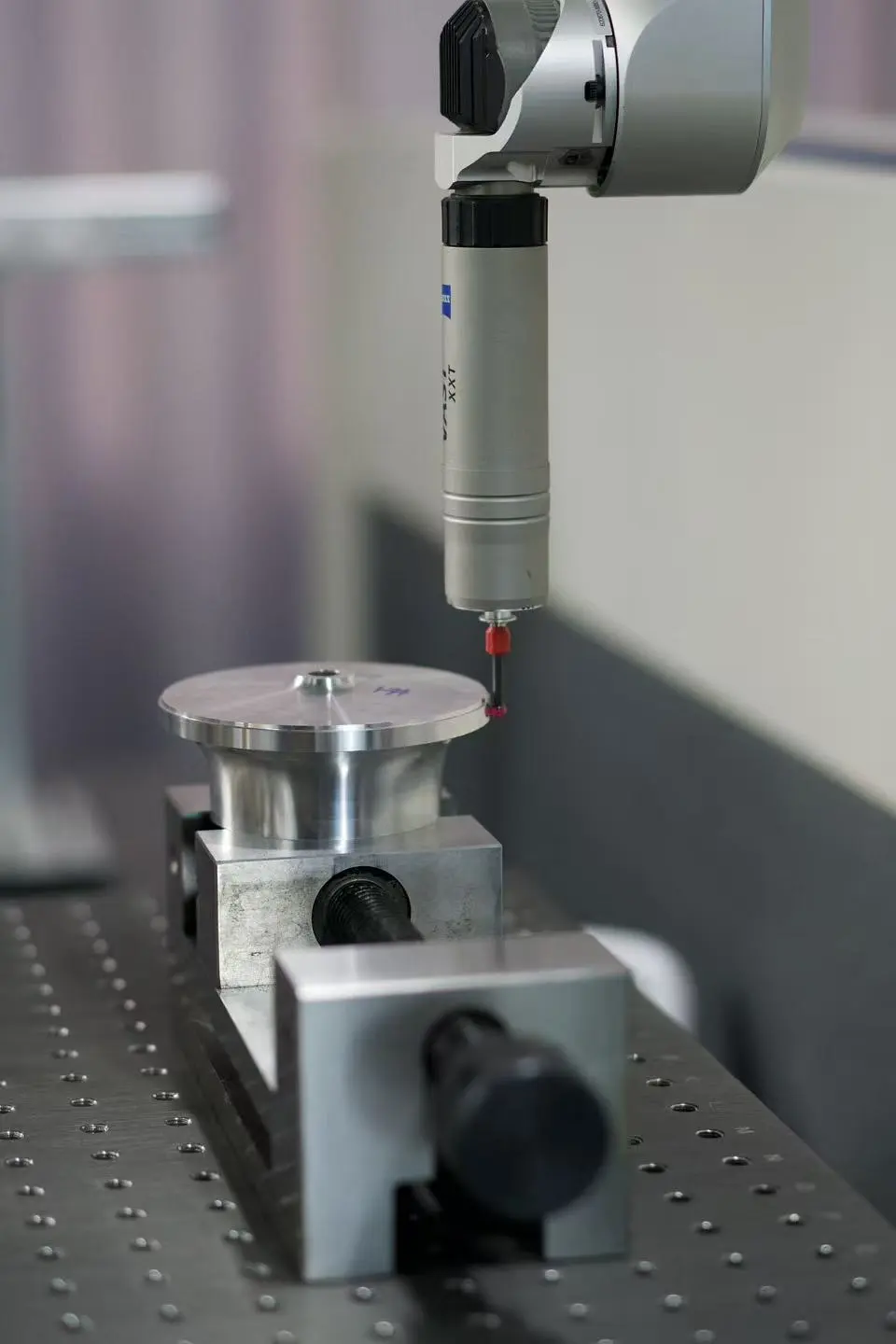

Coordinate Measuring Machine (CMM) Inspection

Coordinate Measuring Machine (CMM) review is a vital strategy for guaranteeing the dimensional exactness of manufactured shafts. This progressive innovation utilizes an exactness test to measure different points on the shaft's surface, making a three-dimensional outline of its geometry. CMM review is especially compelling for fashioned shafts due to its capacity to produce complex shapes and forms with tall exactness. The information collected from CMM assessments can be compared specifically to the plan details, permitting for fast recognizable proof of any deviations. This strategy is particularly important for fashioned shafts utilized in basic applications, where indeed minor dimensional irregularities can lead to execution issues or untimely disappointment. CMM review also empowers producers to keep up tight resiliences throughout the generation process, guaranteeing consistency over clumps of produced shafts.

Optical Measurement Systems

Optical measurement systems have become increasingly popular for inspecting forged shafts, offering rapid and non-contact dimensional analysis for forged shafts. These frameworks utilize advanced cameras and laser technology to capture nitty-gritty pictures of the shaft's surface, which are at that point handled to produce exact estimations. For produced shafts, optical estimation is especially advantageous in evaluating surface highlights, such as grooves, strings, or splines, which may be challenging to measure utilizing contact strategies. The speed and exactness of optical frameworks permit for 100% review of produced shafts in high-volume production situations, upgrading quality control without relinquishing throughput. Moreover, optical estimation can distinguish unpretentious surface abandons that might be missed by other assessment strategies, contributing to the overall quality confirmation of produced shafts.

Manual Gauging and Micrometers

While progressive innovations play a noteworthy part in manufactured shaft review, conventional manual gaging and micrometer estimations stay fundamental tools in the quality control process. These strategies are especially valuable for fast checks amid generation and for confirming basic measurements on manufactured shafts. Manual gauges, such as go/no-go gauges, can quickly evaluate whether a shaft's measurements drop inside indicated tolerances. Micrometers, on the other hand, give exact estimations of breadths and thicknesses, which is significant for guaranteeing the appropriate fit and work of produced shafts in groups. The material nature of these manual strategies permits gifted auditors to identify unobtrusive varieties in surface wrap-up or geometry that might show fundamental issues in the manufacturing process. By combining these conventional strategies with advanced estimation advances, producers can guarantee a comprehensive dimensional review of produced shafts.

How are material properties evaluated in forged shaft inspections?

Hardness Testing

Hardness testing is an essential aspect of assessing the fabric properties of produced shafts. This non-destructive strategy gives important bits of knowledge into the shaft's quality and wear resistance, which are basic components in numerous applications. For manufactured shafts, hardness testing regularly includes strategies such as Rockwell, Brinell, or Vickers hardness tests, depending on the material and particular necessities. These tests determine the shaft's resistance to lasting space, relating to its general quality and strength. In the case of fashioned shafts, hardness testing is especially critical for confirming that the warm treatment process has accomplished the desired fabric properties. Varieties in hardness over distinctive zones of the shaft can also demonstrate potential issues in the fashioning or warm treatment forms, permitting producers to address these concerns some time recently the shaft enters service.

Metallographic Analysis

Metallographic examination is a critical inspection method for assessing the microstructure of forged shafts. This preparation includes carefully planning a test of the shaft fabric, ordinarily by cutting, cleaning, and carving a small area. The arranged test is at that point inspected beneath a magnifying lens to uncover the grain structure, stage composition, and any potential imperfections or irregularities in the fabric. For manufactured shafts, metallographic investigation is especially important in assessing the impact of the manufacturing process on the material's microstructure. It can uncover imperative data on grain estimate and introduction, which directly affect the shaft's mechanical properties. Also, this strategy can identify issues such as considerations, voids, or disgraceful warm treatment that might compromise the integrity of the forged shaft. By conducting exhaustive metallographic examination, producers can guarantee that the producing process has delivered the wanted microstructure for ideal execution and reliability.

Mechanical Property Testing

Mechanical property testing is fundamental for confirming that manufactured shafts meet the required execution determinations. This category of review ordinarily incorporates malleable testing, static quality assurance, and weakness testing. For produced shafts, these tests give basic information on the material's capacity to withstand the stresses and strains experienced amid operation. Pliable testing, for illustration, measures the shaft's extreme malleable quality and stretching, which are key markers of its load-bearing capacity. Surrender quality testing decides the point at which the shaft fabric starts to misshape plastically, an imperative thought for design engineers. Weariness testing is especially vital for produced shafts utilized in energetic applications, as it surveys the material's capacity to withstand repeated cyclic loading without failure. By conducting comprehensive mechanical property testing, producers can guarantee that manufactured shafts will perform dependably beneath their expected working conditions, giving clients with certainty in the product's stability and longevity.

What non-destructive testing methods are used for internal inspection of forged shafts?

Ultrasonic Testing

Ultrasonic testing is a broadly utilized non-destructive method for assessing the inner structure of fabricated shafts. This procedure utilizes high-frequency sound waves to distinguish subsurface abandons, such as breaks, voids, or incorporations, which may not be obvious from the surface. For produced shafts, ultrasonic testing is especially important due to its capacity to enter profound into the fabric, giving a comprehensive appraisal of the shaft's inside integrity. The preparation regularly includes utilizing a transducer to radiate ultrasonic waves into the shaft and analyzing the reflected signals to recognize any irregularities. Progressed ultrasonic strategies, such as staged cluster ultrasonic testing (PAUT), indeed offer more prominent accuracy and the capacity to make nitty gritty 3D pictures of the shaft's inside structure. This level of assessment is significant for guaranteeing the unwavering quality of fashioned shafts in basic applications where internal abandons may lead to disastrous failure.

Magnetic Particle Inspection

Magnetic Particle Inspection (MPI) is another important non-destructive testing method used for forged shafts, especially those made from ferromagnetic materials. This procedure is exceedingly compelling in identifying surface and near-surface absconds such as breaks, creases, or incorporations. The handle includes magnetizing the shaft and applying attractive particles, regularly in a fluid suspension, to its surface. Any discontinuities in the fabric will cause a localized twisting in the attractive field, drawing in the particles and uncovering the imperfection. For fashioned shafts, MPI is particularly valuable in distinguishing stress-induced splits or weariness splits that may create amid benefit. The method's affectability to little absconds makes it an priceless instrument in quality control, permitting producers to capture potential issues some time recently they can lead to shaft disappointment. MPI is regularly utilized in conjunction with other assessment strategies to give a comprehensive appraisal of the manufactured shaft's integrity.

Eddy Current Testing

Eddy Current Testing (ECT) is an advanced non-destructive assessment strategy that is especially valuable for identifying surface and near-surface surrenders in produced shafts. This procedure works by actuating electromagnetic areas in the fabric and analyzing the changes in these areas caused by discontinuities or variations in fabric properties. For manufactured shafts, ECT is profoundly viable in recognizing surface splits, thermal irregularities, and fabric varieties that may influence execution. One of the key points of interest of ECT for fashion shaft review is its capacity to quickly check expansive regions without the requirement for direct contact, making it perfect for high-volume production situations. Furthermore, ECT can be mechanized and integrated into generation lines, permitting for 100% review of produced shafts with negligible effect on throughput. The method's sensitivity to little absconds, and its capacity to distinguish both surface and subsurface irregularities make it a basic instrument in guaranteeing the quality and unwavering quality of fashioned shafts over different industries.

Conclusion

The inspection standards used for forged shafts encompass a wide range of sophisticated methods and technologies, each playing a crucial role in ensuring the quality, reliability, and performance of these critical components. From dimensional accuracy checks using CMMs and optical systems to material property evaluations through hardness testing and metallographic analysis, every aspect of the forged shaft is scrutinized. Non-destructive testing methods such as ultrasonic, magnetic particle, and eddy current testing provide invaluable insights into the internal integrity of the shafts. By adhering to these comprehensive inspection standards, manufacturers can guarantee that forged shafts meet the exacting requirements of their intended applications, providing customers with confidence in the product's durability and long-term performance.

Shaanxi Welong Int'l Supply Chain Mgt Co., Ltd, established in 2001, is a leading provider of customized metal parts for various industries. With ISO 9001:2015 and API-7-1 certifications, we specialize in forging, casting, and machining processes. Our experienced team offers cost-saving solutions, quality control, and timely delivery worldwide. We pride ourselves on meeting product specifications, providing effective packaging, and exceptional customer service. With a global presence and two decades of experience, Welong is committed to driving intelligent manufacturing and international supply chain excellence. For superior forged shafts and other metal components, contact us at info@welongpost.com to experience our dedication to your success.

FAQ

Q: Why are inspection standards important for forged shafts?

A: Inspection standards ensure forged shafts meet quality, safety, and performance requirements, guaranteeing reliability in critical applications.

Q: What is the most common dimensional inspection method for forged shafts?

A: Coordinate Measuring Machine (CMM) inspection is widely used for its precision in measuring complex geometries of forged shafts.

Q: How does hardness testing contribute to forged shaft quality?

A: Hardness testing provides insights into the shaft's strength and wear resistance, verifying proper heat treatment and material properties.

Q: What is the purpose of ultrasonic testing in forged shaft inspection?

A: Ultrasonic testing detects internal defects such as cracks or voids that are not visible from the surface, ensuring the shaft's internal integrity.

Q: Can all inspection methods be used on every type of forged shaft?

A: Not necessarily. The choice of inspection methods depends on the shaft's material, size, and intended application. Some methods are material-specific.

References

1. Smith, J. (2019). Advanced Inspection Techniques for Forged Components. Journal of Materials Engineering and Performance, 28(4), 2145-2160.

2.bJohnson, R. & Brown, T. (2020). Non-Destructive Testing Methods for Forged Shafts: A Comprehensive Review. International Journal of Metalcasting, 14(3), 687-702.

3. Chen, X. et al. (2018). Dimensional Metrology of Forged Shafts Using Optical and Contact Measurement Systems. Measurement Science and Technology, 29(8), 084003.

4. Williams, E. (2021). Material Property Evaluation in Forged Components: Current Practices and Future Trends. Materials Evaluation, 79(5), 526-541.

5. Taylor, M. & Davis, K. (2017). Quality Control in Forging Processes: From Raw Material to Finished Product. ASM Handbook, Volume 14A: Metalworking: Bulk Forming, 321-335.

6. Lee, S. et al. (2022). Advances in Ultrasonic Testing for Internal Defect Detection in Large-Scale Forged Shafts. NDT & E International, 126, 102569.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions