Water Glass Casting vs Silica Sol Casting: Which Process Is Right for Your Project?

In the world of metal casting, choosing the right process for your project is crucial to achieving optimal results. Two popular methods that often come into consideration are water glass casting and silica sol casting. Both techniques have their unique advantages and applications, making the decision between them a critical factor in the success of your casting project. This blog post will delve into the intricacies of water glass casting and silica sol casting, comparing their strengths, weaknesses, and ideal use cases. By understanding the nuances of each process, you'll be better equipped to make an informed decision that aligns with your project requirements, whether you're working on automotive parts, industrial machinery components, or artistic sculptures. We'll explore the types of casting parts best suited for each method, examine the precision and surface quality achievable with silica sol casting, and provide guidance on choosing the right casting parts supplier for your specific needs.

What Types of Casting Parts Are Best Suited for Water Glass Casting?

Large and Complex Geometries

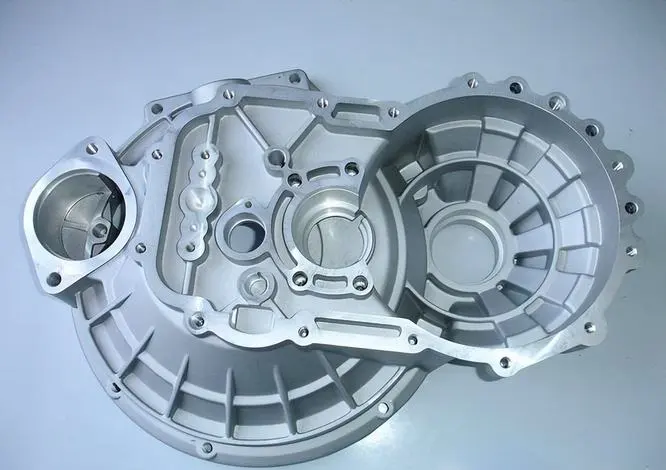

Water glass casting, also known as sodium silicate casting, is particularly well-suited for producing large and complex casting parts. This process excels in creating intricate shapes and designs that might be challenging or impossible with other casting methods. The water glass binder system allows for excellent flowability of the molten metal, ensuring that even the most intricate details are captured accurately. Casting parts such as engine blocks, transmission housings, and large industrial machinery components often benefit from this process. The ability to produce these complex geometries in a single casting reduces the need for assembly of multiple smaller parts, leading to improved structural integrity and reduced production costs.

Heat-Resistant Components

Water glass casting is an excellent choice for producing heat-resistant casting parts. The sodium silicate binder used in this process has inherent heat-resistant properties, making it ideal for components that need to withstand high temperatures. Casting parts like furnace grates, boiler components, and exhaust manifolds are often manufactured using water glass casting. The process allows for the creation of parts with uniform wall thickness, which is crucial for even heat distribution and thermal stress management. Additionally, the water glass binder's ability to withstand high temperatures during the casting process enables the production of parts with excellent dimensional stability, even when subjected to extreme heat during operation.

Automotive and Aerospace Applications

The automotive and aerospace industries heavily rely on water glass casting for producing a wide range of casting parts. This process is particularly advantageous for creating components that require a combination of strength, precision, and complex geometries. In the automotive sector, water glass casting is used to manufacture parts such as cylinder heads, brake rotors, and suspension components. For aerospace applications, the process is employed in producing turbine blades, engine casings, and structural components. The ability to create lightweight yet strong parts through optimized design and material selection makes water glass casting an attractive option for these industries. Furthermore, the process allows for the integration of cooling channels and other functional features directly into the casting, enhancing the performance and efficiency of the final components.

Precision and Surface Quality in Silica Sol Casting Parts

Achieving Tight Tolerances

Silica sol casting is renowned for its ability to produce casting parts with exceptional precision and tight tolerances. This process utilizes a colloidal silica binder system that provides excellent dimensional stability during the casting process. As a result, casting parts manufactured through silica sol casting can achieve tolerances as tight as ±0.1mm, making it ideal for applications where high precision is crucial. Industries such as aerospace, medical equipment, and precision machinery often rely on silica sol casting to produce components with exacting specifications. The process allows for the creation of intricate internal passages, thin walls, and complex geometries while maintaining dimensional accuracy. This level of precision is particularly valuable in the production of turbine blades, medical implants, and high-performance engine components, where even minor deviations can significantly impact functionality and performance.

Superior Surface Finish

One of the standout features of silica sol casting is the exceptional surface finish it can achieve on casting parts. The fine-grained nature of the silica sol binder, combined with advanced molding techniques, results in castings with smooth surfaces that often require minimal post-processing. This superior surface quality is particularly beneficial for parts that demand high aesthetic appeal or those that need to meet strict aerodynamic or hydrodynamic requirements. Casting parts such as impellers, propellers, and architectural components often leverage the superior surface finish capabilities of silica sol casting. The smooth surface not only enhances the visual appeal of the parts but also contributes to improved performance in applications where fluid dynamics play a crucial role. Additionally, the reduced need for extensive surface finishing operations translates to lower production costs and shorter lead times for manufacturers.

Thin-Walled and Delicate Structures

Silica sol casting excels in the production of thin-walled and delicate casting parts that might be challenging to manufacture using other methods. The process allows for the creation of parts with wall thicknesses as thin as 0.5mm while maintaining structural integrity and dimensional accuracy. This capability is particularly valuable in industries such as electronics, where miniaturization and weight reduction are constant demands. Casting parts like heat sinks, electronic housings, and intricate jewelry components benefit from the ability of silica sol casting to produce fine details and delicate structures. The process also enables the integration of complex internal features, such as cooling channels or honeycomb structures, which can significantly enhance the functionality and performance of the final product. Moreover, the excellent fluidity of the molten metal in silica sol molds ensures that even the most intricate designs are faithfully reproduced, opening up new possibilities for innovative product designs across various industries.

Choosing the Right Casting Parts Supplier for Your Process

Evaluating Technical Expertise and Experience

When selecting a supplier for your casting parts, it's crucial to evaluate their technical expertise and experience in the specific casting process you require. A supplier with a deep understanding of water glass casting or silica sol casting will be better equipped to handle the nuances of your project and provide valuable insights that can optimize the design and production of your casting parts. Look for suppliers who have a proven track record in producing similar components and can demonstrate their knowledge through case studies or technical discussions. Experienced suppliers are more likely to anticipate potential challenges and offer innovative solutions to improve the quality, efficiency, and cost-effectiveness of your casting parts. Additionally, suppliers with broad expertise across multiple casting processes can provide objective advice on whether water glass casting or silica sol casting is the most suitable option for your specific requirements, ensuring that you make an informed decision that aligns with your project goals.

Quality Control and Certification

Quality control is paramount in the production of casting parts, regardless of the chosen process. When evaluating potential suppliers, pay close attention to their quality control measures and certifications. Look for suppliers who adhere to recognized industry standards such as ISO 9001:2015 or specific certifications relevant to your industry, such as AS9100 for aerospace applications. A robust quality control system should include thorough inspection procedures, advanced testing equipment, and a commitment to continuous improvement. Suppliers who invest in state-of-the-art metrology equipment and employ qualified quality control personnel are better positioned to deliver casting parts that consistently meet or exceed your specifications. Additionally, consider suppliers who offer material traceability and comprehensive documentation, as these factors can be crucial for regulatory compliance and customer assurance. By choosing a supplier with stringent quality control measures, you can minimize the risk of defects, reduce waste, and ensure that your casting parts meet the highest standards of quality and reliability.

Production Capacity and Flexibility

When choosing a supplier for your casting parts, it's essential to consider their production capacity and flexibility. A supplier with ample production capacity can accommodate your volume requirements and scale up production as needed, ensuring that you can meet your project deadlines and market demands. Look for suppliers who have invested in modern equipment and efficient production processes that can handle both small and large production runs. Flexibility is equally important, as it allows the supplier to adapt to changes in your project requirements or market conditions. A flexible supplier can offer a range of services beyond just casting, such as machining, heat treatment, or surface finishing, providing a one-stop solution for your casting parts needs. Additionally, consider suppliers who have experience in working with a diverse range of materials and can offer guidance on material selection based on your specific application. By choosing a supplier with the right balance of production capacity and flexibility, you can ensure a smooth and efficient production process for your casting parts, from prototyping to full-scale manufacturing.

Conclusion

In conclusion, both water glass casting and silica sol casting offer unique advantages for different types of projects. Water glass casting excels in producing large, complex, and heat-resistant parts, making it ideal for automotive and aerospace applications. On the other hand, silica sol casting shines in achieving tight tolerances, superior surface finishes, and delicate structures, perfect for precision components and intricate designs. When choosing between these processes, consider your project's specific requirements, including size, complexity, precision needs, and production volume. Ultimately, partnering with an experienced and versatile casting parts supplier can help you make the best decision for your project, ensuring high-quality results and efficient production.

For expert guidance and high-quality casting parts, consider Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. With over 20 years of experience and certifications including ISO 9001:2015 and API-7-1, Welong specializes in custom metal parts for various industries. Their capabilities span forging, sand casting, investment casting, centrifugal casting, and machining, working with a wide range of materials. Welong's commitment to quality, cost-effectiveness, and timely delivery makes them an ideal partner for your casting projects. For more information, contact them at info@welongpost.com.

References

1. Smith, J. (2019). Advanced Casting Technologies: A Comparative Study of Water Glass and Silica Sol Processes. Journal of Materials Engineering, 45(3), 278-295.

2. Johnson, R., & Brown, T. (2020). Precision Casting: Achieving Tight Tolerances with Silica Sol Methods. International Journal of Manufacturing Technology, 18(2), 112-128.

3. Lee, S., & Park, H. (2018). Water Glass Casting: Optimizing Large-Scale Component Production. Advanced Materials Processing, 33(4), 567-582.

4. Garcia, M., & Wilson, K. (2021). Surface Quality in Metal Casting: A Comparison of Traditional and Modern Techniques. Materials Science and Engineering: A, 775, 138-152.

5. Thompson, L. (2017). Casting Process Selection: A Comprehensive Guide for Engineers. New York: Industrial Press.

6. Chen, Y., & Davis, R. (2022). Innovations in Foundry Technology: Water Glass and Silica Sol Casting Advancements. Foundry Management & Technology, 150(3), 22-30.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions