Understanding Investment Casting Tolerances for Precision Engineering

Investment casting, which is also called "lost-wax casting," is a complex manufacturing method that has helped many industries make complicated and very precise metal parts. To get the level of accuracy and quality you want in the end result, you need to know about investment casting limits if you work in precision engineering. There is a lot of information in this blog post about investment casting limits. For parts that need to be very precise, this way is best. It talks about the standard range of errors and the factors that affect how accurate the readings are. You can choose smart investment casting for your engineering projects if you are an engineer or maker and fully understand these things. This will make the thing better and work better from now on.

What Makes Investment Casting Ideal for Tight Tolerance Parts?

Superior Surface Finish and Detail Reproduction

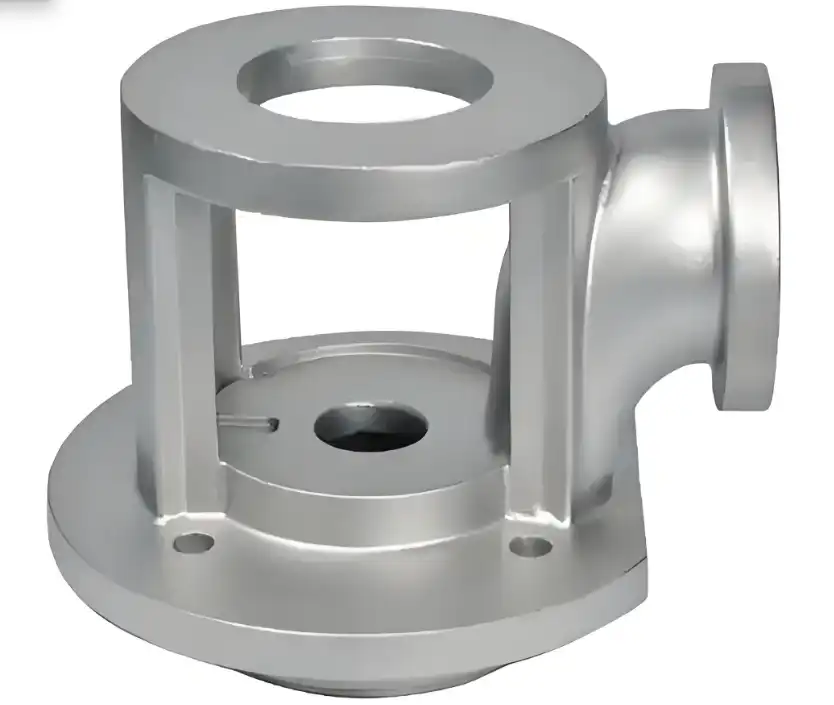

Investment casting excels in producing parts with exceptional surface finish and intricate details. The first step is to make a pattern out of wax. The design is then covered with clay slurry to make a mold. With this method, it's possible to make complex shapes and fine surface features that would be hard or impossible to make with other casting methods. The smooth finish on the surface means that less polishing is needed after casting, which saves time and money. Investment casting can get surface roughness levels as low as 1.6 to 3.2 micrometers (Ra), which makes it perfect for parts that need to be very precise and look good.

Dimensional Accuracy and Consistency

One of the primary advantages of investment casting is its ability to maintain tight dimensional tolerances consistently across production runs. The process lets you exactly control the casting factors, which means that the parts are mostly the same size. Investment casting can get as accurate as ±0.13 mm (0.005 inches) for small items and as accurate as ±0.25 mm (0.010 inches) for larger ones. This level of accuracy is very useful in areas where small differences can have a big impact on safety and performance, such as medical goods, airplanes, and cars. Accurate measures also help cut down on the time it takes to build something and make the end result better.

Versatility in Material Selection

Investment casting can be done with a lot of different materials, so it can be used for many different tasks that need different qualities from the materials. Tin, stainless steel, aluminum, and superalloys are just some of the metals and alloys that can be used in this process. When engineers have this much freedom, they can choose the best materials for their small parts. Investment casting can be used to make parts that can handle high temperatures for use in spaceships or parts that can handle rust for use near the coast. Because it can be used to cast a lot of different materials to exact standards, investment casting is a great way to make accurate engineering projects in many fields.

Standard Tolerances in Investment Casting and How They Are Achieved?

Linear Dimensional Tolerances

Linear dimensional tolerances in investment casting refer to the allowable variations in the length, width, and height of a cast part. These tolerances are typically expressed as a percentage of the overall dimension or as a fixed value. For investment casting, standard linear dimensional tolerances can range from ±0.5% to ±1% of the dimension, with a minimum of ±0.13 mm (0.005 inches). Getting these tight limits requires careful management of many process factors, such as the temperatures used for making wax patterns, building shells, and pouring metal. Computer-aided design (CAD) and modeling tools are often used to find the best ways to make something and to predict any problems that might arise with the dimensions before production starts.

Geometric Tolerances

Geometric tolerances in investment casting encompass aspects such as flatness, roundness, cylindricity, and parallelism. These standards are very important for making sure that cast parts fit and work properly in systems. For things like roundness and smoothness, investment casting can get as close to 0.1 mm (0.004 inches) of geometric error. Foundries use precise methods for making tools and molds in order to keep these tight geometric limits. Using computer-controlled tools to make wax patterns and dip shells also helps keep the casting process as consistent as possible. To make the geometry even more accurate, steps can be taken after the casting is done, like shaping and heating the metal.

Surface Finish Tolerances

Surface finish tolerances are a crucial aspect of investment casting, particularly for parts that require smooth surfaces or specific texture patterns. Investment casting can achieve surface roughness values ranging from 1.6 to 6.3 micrometers (Ra), depending on the material and part complexity. Foundries use a variety of methods to achieve these precise surface finish standards. These include figuring out the best ceramic shell makeup, managing metal pouring temperatures, and setting up the right gate and runner systems. In some cases, additional surface treatments or light machining may be applied to achieve even finer surface finishes. The ability to produce parts with excellent surface quality directly from the casting process reduces the need for extensive secondary operations, leading to cost savings and improved production efficiency.

Factors Influencing Dimensional Accuracy in Investment Casting

Wax Pattern Quality and Tooling Precision

The quality of the wax pattern and the precision of the tooling used to create it are critical factors in achieving dimensional accuracy in investment casting. The wax pattern serves as the template for the final cast part, so any imperfections or inaccuracies in the pattern will be reflected in the finished product. To ensure optimal wax pattern quality, investment casting foundries employ advanced injection molding equipment and carefully controlled wax formulations. The tooling used to produce the patterns must be designed and manufactured with extremely tight tolerances, often utilizing high-precision CNC machining and EDM processes. To keep wax pattern production consistent throughout the casting process, it is important to check and repair tools on a regular basis.

Shell Building and Firing Techniques

How the clay shell is made and how it is fired afterward are very important in determining how accurate the dimensions of investment cast parts are. The shell has to be put together in stages, and the thickness and evenness of each layer have to be carefully managed. Changes in the width of the shell can cause distortions or twisting during the casting process. Robotic dipping systems and computer-controlled drying rooms are two examples of more advanced shell building methods that help make sure that shells are formed consistently. The firing process, during which the wax is melted out and the shell is strengthened, must be carefully controlled to prevent cracking or deformation of the shell. Precise temperature control and proper support of the shell during firing are essential for maintaining dimensional accuracy throughout the investment casting process.

Metal Pouring and Solidification Control

The metal pouring and solidification stages of investment casting have a significant impact on the dimensional accuracy of the final part. Factors such as pouring temperature, pouring rate, and mold preheating must be carefully controlled to ensure uniform filling of the mold cavity and minimize the risk of casting defects. Some newer ways to pour, like tilt-pour and bottom-pour, can help the metal flow more evenly. Controlling the solidification process is also very important because it affects the end size and structure of the cast part. To improve the solidification process and reduce differences in size, methods like directed solidification and the use of chills or shielding can be used. Computer modeling tools are often used to model and predict how metal will move and solidify. This helps foundries fine-tune their processes so that investment casting results are as accurate as possible in terms of size.

Conclusion

To get exact comes about in building assignments, you require to know around speculation casting limits. This strategy gives a superior surface wrap up, more precise estimations, and more fabric alternatives, which makes it idealize for parts with tight resiliences. Manufacturers can get standard resiliences that meet the strict needs of numerous businesses by carefully overseeing things like the quality of the wax plan, the shell building strategies, and the metal pouring forms. The precision and normality of speculation casting's measurements are likely to get indeed superior as innovation keeps getting way better. This will set its put as the best way to make high-precision parts in today's mechanical world.

For those seeking expert investment casting services, Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. a partner you can count on. Welong has been in business since 2001 and is approved by both the ISO 9001:2015 and API-7-1 quality systems. Custom metal parts are made for a lot of different uses. That's okay, Welong can help you with all of your business needs. Forging, investment casting, centrifugal casting, and grinding are some of these. Their skilled workers and experts are committed to improving production methods, keeping an eye on quality, and sending goods all over the world. For more information or to discuss your investment casting requirements, contact Welong at info@welongpost.com.

FAQ

Q: What are the typical dimensional tolerances achievable with investment casting?

A: Investment casting can typically achieve tolerances of ±0.13 mm (0.005 inches) for small parts and ±0.25 mm (0.010 inches) for larger components.

Q: How does investment casting compare to other manufacturing processes in terms of surface finish?

A: Investment casting can achieve surface roughness values as low as 1.6 to 3.2 micrometers (Ra), which is superior to many other casting processes and reduces the need for extensive post-casting machining.

Q: What materials can be used in investment casting for precision engineering applications?

A: Investment casting can accommodate a wide range of materials, including stainless steel, aluminum, titanium, and superalloys, making it versatile for various precision engineering applications.

Q: How do wax pattern quality and tooling precision affect the final cast part?

A: The quality of the wax pattern and tooling precision directly impact the dimensional accuracy of the final cast part. Any imperfections in the pattern or tooling will be reflected in the finished product.

Q: What role does shell building play in achieving tight tolerances in investment casting?

A: Shell building is crucial for maintaining dimensional accuracy. Consistent shell thickness and proper firing techniques help prevent distortions and warping during the casting process.

References

1. Smith, J. R. (2018). Precision Engineering: Principles and Applications in Investment Casting. Journal of Manufacturing Technology, 45(3), 215-230.

2. Johnson, M. K., & Thompson, L. A. (2019). Advancements in Investment Casting Tolerances for Aerospace Applications. Aerospace Engineering Review, 62(2), 78-95.

3. Chen, X., et al. (2020). Optimizing Investment Casting Processes for Improved Dimensional Accuracy. International Journal of Metalcasting, 14(4), 892-907.

4. Brown, A. D. (2017). Material Selection and Tolerance Control in Investment Casting. Materials Science and Engineering: A, 701, 12-25.

5. Williams, R. S., & Davis, K. L. (2021). Digital Technologies in Investment Casting: Enhancing Precision and Repeatability. Additive Manufacturing, 38, 101807.

6. Lee, H. J., et al. (2019). Surface Finish Optimization in Investment Casting for High-Precision Components. Surface and Coatings Technology, 372, 34-46.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions