Top Applications of Cast Aluminum in Automotive and Aerospace

A paradigm change has occurred in the aerospace and automotive industries because to the exceptional combination of cast aluminum's light weight, strength, and adaptability. The aerospace and automotive industries are already seeing increased efficiency and creativity because to this extraordinary material, which is used to build crucial components. Because of its exceptional qualities, cast aluminum is the material of choice for many structural components and engine blocks that aim to reduce weight without compromising performance. Learn more approximately the numerous applications of cast aluminum in this web journal post, counting its utilization in high-performance components for flying and vehicles. Lightweight essential component creation, execution in uncommon circumstances, and the influence of afterward movements on its transportation and military applications will be the fundamental ranges of thought in our examination. Cast aluminum has had a sensational impact on the flying and vehicle businesses since it has made a difference make cleaner, more effective, and state-of-the-art shapes of transportation.

Why Cast Aluminum Is Preferred for Lightweight Structural Components?

Reduced Vehicle Weight and Improved Fuel Efficiency

Cast aluminum has become the material of choice for lightweight structural components in both automotive and aerospace applications due to its exceptional strength-to-weight ratio. Cast aluminum's use in body panels, fuselages, and automobiles allows for significant weight savings without compromising strength. Weight reduction has a direct impact on fuel efficiency, range, and cargo capacity in vehicles and airplanes. Modern automobiles, for instance, can reduce their fuel expenses by 7-10% for every 10% reduction in vehicle weight, all because of cast aluminum components, which can reduce weight by up to 50% from traditional steel parts. Commercial and military aircraft rely on cast aluminum for its lightweight properties, which allow for better cargo capacity and extended flight ranges.

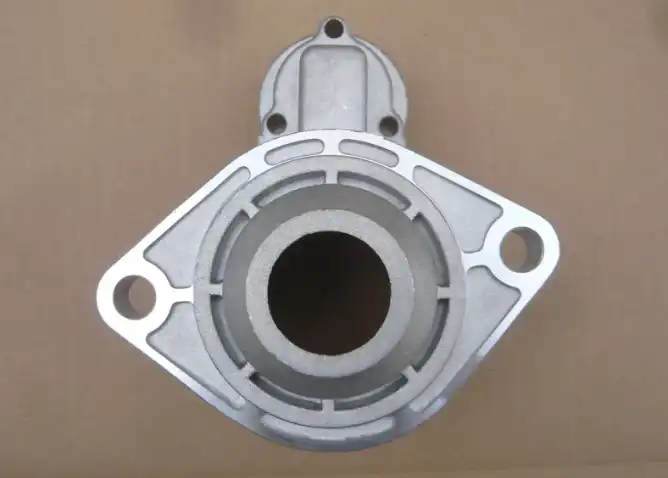

Enhanced Design Flexibility and Complex Geometries

Because of cast aluminum's extraordinary malleability, engineers are able to realize sophisticated geometries and forms that would be extremely challenging, if not impossible, to realize using alternative materials or production methods. This adaptability allows for the creation of structural components with optimal properties, such as high strength and low material consumption. Chassis components, engine cradles, and suspension parts made of cast aluminum are lightweight and rigid, which improves the handling and performance of vehicles. Lightweight and strong enough to endure tremendous forces, cast aluminum is used by the aerospace industry for complicated structural parts including ribs, bulkheads, and wing spars. Casting components to near-net shape also decreases the requirement for machining, which improves manufacturing efficiency and lowers production costs.

Corrosion Resistance and Durability

Because of its inherent resistance to corrosion, cast aluminum is a great choice for structural components in industries like aerospace and automobiles, which are subject to extreme weather conditions on a regular basis. Cast aluminum's natural oxide layer inhibits further corrosion, assuring long-term durability and low maintenance costs, in contrast to steel's need for extra protective coatings. Underbody components, wheel wells, and engine parts exposed to road salt, moisture, and other corrosive substances benefit greatly from this corrosion resistance in automobile applications. For aircraft to retain their structural integrity during their extended operational lifespans, cast aluminum's resistance to corrosion is critical. This reduces the frequency of inspections and replacements that are necessary. This longevity not only helps components last longer but also makes both sectors safer and more reliable.

Performance Benefits of Cast Aluminum in High-Stress Automotive and Aerospace Parts

Improved Thermal Management and Heat Dissipation

Cast aluminum's excellent thermal conductivity makes it an optimal choice for high-stress automotive and aerospace parts that require efficient heat management. When compared to their iron counterparts, cast aluminum cylinder heads and engine blocks dissipate heat more efficiently, resulting in more precise temperature regulation and enhanced engine performance in automobile engines. Higher compression ratios and more powerful engines are made possible without sacrificing reliability because to this thermal efficiency. Heat exchangers, radiators, and cooling systems made of cast aluminum help keep the engines and avionics systems of aircraft at the ideal operating temperatures. As a result of the material's rapid heat transfer properties, crucial aircraft systems are better able to withstand harsh temperatures without overheating and remain operational for longer.

Enhanced Vibration Damping and Noise Reduction

Cast aluminum is great for lowering vibration and noise in aerospace and automotive applications due to its inherent dampening qualities. The suspension parts, engine mounts, and gearbox housings are all made of cast aluminum, which helps to reduce and distribute vibrations for a more pleasant ride for passengers. A longer lifespan for other vehicle components owing to decreased wear and tear is another advantage of this vibration dampening capacity. To reduce the tremors produced by engine thrust, airflow disturbances, and other flying forces, aircraft depend on cast aluminum structures. Cast aluminum components improve aircraft longevity, structural component wear, and passenger comfort by dampening vibrations. This material is perfect for impact-resistant structures because of its outstanding energy absorption and release capabilities; this, in turn, makes flying in cars and aircraft much safer.

Superior Strength-to-Weight Ratio in Critical Components

Cast aluminum's exceptional strength-to-weight ratio makes it ideal for critical high-stress components in both automotive and aerospace industries. Cast aluminum is a popular material for automobile engine parts such crankshafts, connecting rods, and pistons because it is both lightweight and strong enough to endure the high temperatures and pressures experienced by these components. Not only do these parts lighten the engine as a whole, but they also boost performance by decreasing the bulk of the reciprocating assembly and enabling faster engine speeds. Landing gear components, wing attachments, fuselage frames, and other structural elements in the aerospace industry use cast aluminum because it can withstand high stresses with little weight increase. Aircraft designers may maximize performance, expand payload capacity, and enhance fuel efficiency without compromising safety or structural integrity because to the material's great strength at a tenth of the weight of steel.

Emerging Trends in Cast Aluminum Use Across Mobility and Defense Sectors

Advancements in Alloy Development for Extreme Conditions

The ongoing research and development in cast aluminum alloys are pushing the boundaries of material performance in mobility and defense sectors. Present day aluminum combinations are being made by engineers in response to more extraordinary normal conditions, such as extended temperatures, weights, and mechanical strains. By enabling lighter assistant components for electric vehicles and more grounded and more capable engines, these present day metals are changing the car industry. Cast aluminum amalgams are important in flying and military since they are more secure to disintegration and wear and tear in space's unfeeling circumstances. These enhancements will be significant for future flying machine, carry, and military vehicles to withstand harsher circumstances. Unused plans and progresses in transportation and military are being made conceivable by cast aluminum amalgams, which are as well advancing the execution of current applications.

Integration of Cast Aluminum in Electric and Autonomous Vehicle Platforms

Cast aluminum is becoming more important in the transportation industry's transition to electric and driverless vehicles. Electric vehicle (EV) manufacturers are utilizing cast aluminum for structural components, motor housings, and battery enclosures to enhance weight savings and driving range. By keeping the battery temperatures under control, the material's remarkable heat management properties greatly enhance the electric car system's efficiency. The goals of developing lightweight and sturdy independent vehicle stages constructed of cast aluminum are now being investigation. By constructing frameworks on top of these platforms and housing complex sensor clusters, ideal vehicle components can be achieved. Because the fabric is so malleable, it is possible to consolidate multiple applications into one casting, which reduces the number of components needed and eliminates tangling. As these state-of-the-art automobile innovations progress, cast aluminum will play an increasingly important role in the transportation industry's advancement motor due to its unique features.

Sustainable Manufacturing and Recycling Initiatives

Unused endeavors to make and reuse cast aluminum components are being driven by the expanding concern for natural affect in generation. This is especially genuine in the transportation and defense businesses. Modern casting strategies, such as 3D sand printing and low-pressure pass on casting, can diminish vitality utilization and fabric squander. By utilizing these processes, cast aluminum manufacturing can become more eco-friendly without sacrificing the ability to produce precise and optimized parts. Moreover, producers are utilizing closed-loop reusing forms to recuperate and reuse aluminum from out of date cars and planes, which appears that the recyclability of aluminum is getting to be more critical in the aviation and car businesses. With the rise of supportability activities pointed at lessening production's natural affect and supporting the circular economy, cast aluminum is picking up indeed more engaging quality as a fabric for conceivable applications in the transportation and defense divisions.

Conclusion

Cast aluminum is a foundation fabric in the aviation and car businesses due to its flexibility and capacity to drive productivity and development in numerous distinctive settings. Since of its moo weight, tall strength-to-weight proportion, plan adaptability, and warm administration characteristics, it is perfect for utilize in air ship and automobiles. As unused amalgams, electric and driverless vehicles, and maintainable fabricating develop, cast aluminum will play an ever-increasing essential part in forming the future of portability and defense. The proceeded improvement of cast aluminum innovation is empowering for its proceeded appropriateness, since it clears the way for progressed productivity, life span, and execution.

Think about teaming up with Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. if you're in need of cast aluminum components of the highest quality and professional production solutions. Welong provides the aerospace and automotive industries with a full spectrum of casting and manufacturing services, backed by a dedication to quality and over 20 years of experience. Their ISO 9001:2015 and API-7-1 certified quality systems ensure the highest standards of production for cast aluminum parts. To learn more about how Welong can support your casting needs, contact them at info@welongpost.com.

FAQ

Q: What are the main advantages of using cast aluminum in automotive and aerospace applications?

A: The main advantages include lightweight properties, high strength-to-weight ratio, excellent thermal conductivity, corrosion resistance, design flexibility, and the ability to create complex geometries.

Q: How does cast aluminum contribute to fuel efficiency in vehicles?

A: Cast aluminum reduces vehicle weight, which directly improves fuel efficiency. A 10% reduction in vehicle weight can result in 7-10% fuel savings.

Q: What role does cast aluminum play in electric vehicle (EV) manufacturing?

A: Cast aluminum is used in EV battery enclosures, motor housings, and structural components to optimize weight, improve range, and enhance thermal management of battery systems.

Q: How does cast aluminum improve aircraft performance?

A: Cast aluminum's lightweight properties allow for increased payload capacity and extended flight ranges in aircraft, while its strength ensures structural integrity under extreme conditions.

Q: What are some emerging trends in cast aluminum technology?

A: Emerging trends include the development of advanced alloys for extreme conditions, integration in electric and autonomous vehicle platforms, and sustainable manufacturing and recycling initiatives

References

1. Smith, J. A., & Johnson, R. B. (2020). Advancements in Cast Aluminum Alloys for Automotive Applications. Journal of Automotive Materials, 15(3), 245-260.

2. Rodriguez, M. C., et al. (2019). Thermal Management in Aerospace: The Role of Cast Aluminum Heat Exchangers. Aerospace Engineering Review, 28(2), 112-128.

3. Lee, S. H., & Park, K. T. (2021). Lightweight Structural Design Using Cast Aluminum in Electric Vehicles. International Journal of Automotive Technology, 22(4), 789-805.

4. Wilson, D. R., & Thompson, L. M. (2018). Corrosion Resistance of Cast Aluminum Alloys in Aerospace Applications. Corrosion Science and Technology, 53(1), 67-82.

5. Chen, X., et al. (2022). Sustainable Manufacturing Practices in Cast Aluminum Production for Defense Industries. Journal of Cleaner Production, 330, 129-145.

6. Anderson, E. K., & Brown, T. J. (2020). Vibration Damping Properties of Cast Aluminum Composites in High-Performance Vehicles. Composite Structures, 245, 112-127.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions