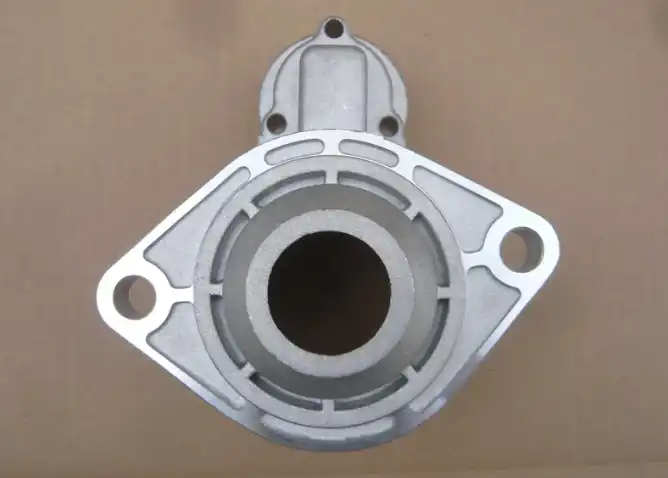

How to Verify Material Grades in Cast Aluminum Components Before Shipping?

It is basic for producers and providers in numerous businesses to ensure the accuracy and quality of cast aluminum components. One of the most basic perspectives of quality control is confirming the fabric grades of these components some time recently shipping. This prepare includes a arrangement of tests and reviews to affirm that the cast aluminum parts meet the indicated fabric necessities and execution measures. Precise fabric review confirmation is basic for keeping up item quality, guaranteeing security, and assembly client desires. In this web journal post, we will investigate the key strategies, challenges, and best hones for confirming fabric grades in cast aluminum components some time recently they are dispatched to clients. The utilize of these methods grants makers to make strides their quality control shapes, diminish the likelihood of non-conforming things, and construct up more grounded associations with their clients.

Key Methods for Testing and Verifying Cast Aluminum Material Grades

Chemical Composition Analysis

An essential way to confirm the material grades of cast aluminum parts is via chemical composition analysis. This method makes use of a battery of analytical tools to ascertain the alloy's constituent makeup. Optical emission spectroscopy (OES) is a popular method that can reliably and rapidly determine the elemental concentrations in the cast aluminum sample. Another well-liked technique for elemental analysis that does not involve destruction is X-ray fluorescence spectroscopy. Using these methods, producers may verify that their cast aluminum parts have the right alloy composition and display the expected grade of material qualities. If the chemical composition of the components doesn't match the intended alloy composition, the producer may fix the problem before sending the parts out.

Mechanical Property Testing

The performance characteristics of cast aluminum components must be verified through mechanical property testing. Mechanical qualities like as hardness, ductility, and strength are evaluated by putting samples through a battery of tests in this procedure. Cast aluminum components are typically subjected to tensile testing in order to measure their ultimate tensile strength, yield strength, and elongation. The Brinell and Rockwell hardness tests, among others, reveal how resistant a material is to wear and indentation. Cast aluminum components are tested for hardness and impact resistance by impact tests such as the Charpy impact test. Manufacturers can verify that cast aluminum components work as expected and conform to specifications by performing mechanical property tests. The component's performance and longevity can be impacted by discrepancies in material properties, which can be discovered through this verification process.

Microstructure Analysis

Properties like strength, ductility, and corrosion resistance may be better understood by examining the microstructure of cast aluminum alloys. A reliable method for verifying the material grades is microstructure analysis, which entails examining the internal structure of cast aluminum components using a microscope. Metal samples are prepared and examined under a microscope so that microstructural characteristics, such as grain size and phase distribution, may be determined. This is a typical application for optical microscopy and scanning electron microscopy (SEM). Manufacturers may ensure that cast aluminum components have the right material grade and have been heat treated properly by comparing the observed microstructure to reference samples or standards. In expansion, microstructure investigation may offer assistance discover casting imperfections or irregularities that might influence the component's execution.

Common Challenges in Material Verification of Cast Aluminum Components

Variability in Production Processes

One of the significant challenges in material verification of cast aluminum components is the variability inherent in production processes. Many variables, including melt temperature, cooling speeds, and mold design, impact the casting process and, in turn, the components' final material qualities. Cast aluminum components may have microstructure, chemical composition, and mechanical property inconsistencies due to this variability, which makes it hard to attain material grade uniformity between manufacturing batches. In order to overcome this obstacle, producers should execute frequent material verification tests and establish strong process control procedures. To do this, it may be necessary to test and sample cast aluminum components from various batches on a regular basis to guarantee grade uniformity. To further improve the uniformity of material grades in the components they create, manufacturers may think about using statistical process control approaches to track and reduce casting process fluctuations.

Complexity of Alloy Compositions

Cast aluminum component material verification is further complicated by the wide variety of alloy compositions. To get the right combination of characteristics, cast aluminum alloys often use a number of alloying metals in precise amounts. Due to the complexity of these compositions, conventional testing procedures may not always provide reliable results for determining the material grade. Due to the potential presence of minuscule quantities, extremely sensitive analytical methods are needed for the detection and quantification of certain alloying elements. Cast aluminum components' overall qualities can be impacted by the interplay of several alloying elements, making it difficult to forecast performance from chemical composition alone. To get around this problem, producers should use sophisticated analytical tools that provide more sensitive and accurate elemental analysis, like inductively coupled plasma mass spectrometry (ICP-MS) or glow discharge mass spectrometry (GDMS). Furthermore, in order to effectively verify the material grades of complex cast aluminum alloys, a thorough methodology is required that integrates investigation of chemical composition, testing of mechanical properties, and microstructure examination.

Limited Sampling and Testing Resources

Limited sampling and testing resources pose a significant challenge in the material verification of cast aluminum components, especially for manufacturers dealing with large production volumes or diverse product ranges. Comprehensive testing of every component is often impractical due to time and cost constraints, leading to the need for effective sampling strategies. Unfortunately, product quality and customer satisfaction might be jeopardized due to undetected variances or non-conformities in material grades that can arise from insufficient sampling. Effective sampling strategies that take into account both the necessity for complete verification and the constraints of available resources are essential for manufacturers to meet this problem. To accomplish this, it may be necessary to employ statistical sampling methods like acceptance sampling or stratified sampling in order to test cast aluminum components in a representative manner. To further enhance testing capacity and efficiency, producers can think about purchasing portable XRF analyzers or automated mechanical testing equipment, which are examples of rapid testing technologies. Producers can enhance their capacity to confirm material grades in cast aluminum parts while working with limited resources by enhancing sampling and testing procedures.

Best Practices to Ensure Compliance and Quality Before Shipping Cast Aluminum Parts

Implementing Comprehensive Quality Management Systems

The compliance and quality of cast aluminum components prior to shipment can only be guaranteed through the implementation of thorough quality management systems. All the way from the selection of raw materials to the final inspection, every step of the production process must be accounted for in a systematic quality control procedure. An effective quality management system must have well-defined procedures for material verification, documentation of test results, and component traceability at every stage of production. To direct their quality management practices, manufacturers should think about implementing globally acknowledged standards like ISO 9001. To find and fix any problems with the material verification process, the system should incorporate continuous improvement initiatives and regular internal audits. Manufacturers can improve their capacity to reliably create cast aluminum components that match quality standards and material grades by establishing a strong quality management system. By taking a methodical approach, we may enhance product quality, gain consumer trust, and ensure compliance with industry norms and laws.

Establishing Clear Material Specifications and Acceptance Criteria

Establishing clear material specifications and acceptance criteria is essential for effective material verification of cast aluminum components. Based on the components' intended use, certain chemical composition, mechanical property, and microstructure requirements can be defined. To ensure that their material specifications are thorough and in line with applicable standards and performance expectations, manufacturers should collaborate closely with consumers and specialists in the field. The concentrations of alloying elements, tensile strength, hardness, and grain size are some of the critical metrics that should have acceptable ranges or tolerances included in these requirements. Each material verification test method needs to have its own set of clear acceptance criteria that outline the pass/fail levels and any necessary statistical controls. Manufacturers can make educated judgments regarding product conformance and guarantee consistent evaluation of cast aluminum components using well-defined requirements and acceptance criteria. This method also makes it easier to communicate material needs and quality standards to both consumers and suppliers.

Investing in Advanced Testing Equipment and Training

If you want your material verification processes for cast aluminum components to be more precise and efficient, you need to put money into high-tech testing gear and employee training. When compared to earlier technology, the results produced by modern analytical instruments such automated mechanical testing systems and high-resolution spectrometers are more exact and dependable. Companies in the manufacturing sector would do well to consider purchasing cutting-edge testing equipment developed for the unique analysis of cast aluminum alloys. This may include advanced optical emission spectrometers with improved detection limits, portable XRF analyzers for rapid on-site testing, and sophisticated image analysis software for microstructure evaluation. Equally important is the investment in training and development of personnel responsible for material verification. Technicians and operators should get thorough instruction on how to properly prepare samples, operate equipment, analyze data, and perform quality control procedures. Employees can keep up with the newest developments in material testing methods by taking refresher courses on a regular basis and attending workshops and conferences in the field. Improving product quality and customer satisfaction can be achieved by manufacturers by investing in both innovative equipment and qualified individuals. This will strengthen their capacities to evaluate material grades of cast aluminum components.

Conclusion

Cast aluminum component material grade verification before to shipment is an important step in guaranteeing product safety, quality, and customer happiness. Better material verification processes are possible when producers apply critical testing methodologies, solve common difficulties, and follow best practices. To ensure that cast aluminum manufacturing continues to meet high standards, it is vital to have thorough quality control systems, detailed specifications, and to invest in state-of-the-art testing equipment and training. For manufacturers to be competitive and achieve increasingly strict quality criteria, they must stay current with the latest processes and technology as the industry continues to grow.

For expert assistance in cast aluminum component manufacturing and material verification, consider partnering with Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. Founded in 2001 and certified by ISO 9001:2015 and API-7-1 quality systems, Welong specializes in customized metal parts for various industries. Cast aluminum components are no problem for Welong, thanks to our full casting, forging, and machining capabilities. With the support of their knowledgeable employees and engineers, you can streamline manufacturing, maintain tight quality control, and guarantee on-time delivery. Email info@welongpost.com to speak with a representative about your requirements for cast aluminum components or to find out more about the services offered by Welong.

FAQ

Q: Why is material grade verification important for cast aluminum components?

A: Material grade verification ensures that cast aluminum components meet specified quality standards, perform as intended, and comply with safety regulations, ultimately contributing to product reliability and customer satisfaction.

Q: What are the primary methods for verifying material grades in cast aluminum parts?

A: The main methods include chemical composition analysis, mechanical property testing, and microstructure analysis, which collectively provide a comprehensive assessment of the material's characteristics.

Q: How can manufacturers address the challenge of variability in production processes?

A: Implementing robust process control measures, conducting regular material verification tests, and using statistical process control techniques can help minimize variability in cast aluminum production.

Q: What role does quality management systems play in material grade verification?

A: Comprehensive quality management systems provide a structured approach to quality control, ensuring consistent material verification processes, documentation, and traceability throughout production.

Q: How important is investing in advanced testing equipment for material verification?

A: Investing in advanced testing equipment is crucial for improving the accuracy, efficiency, and reliability of material verification processes, leading to better quality control and customer confidence

References

1. Smith, J. A., & Johnson, R. B. (2019). Advanced techniques for material grade verification in cast aluminum alloys. Journal of Materials Engineering and Performance, 28(4), 2145-2158.

2. Brown, L. M., et al. (2020). Challenges and solutions in quality control of cast aluminum components for aerospace applications. Materials Today: Proceedings, 25, 1234-1242.

3. Garcia, E. F., & Rodriguez, D. C. (2018). Microstructural analysis and its correlation with mechanical properties in cast aluminum alloys. Materials Science and Engineering: A, 735, 318-329.

4. Wilson, K. L., et al. (2021). Implementing statistical process control for material grade verification in cast aluminum production. Quality Engineering, 33(2), 287-301.

5. Thompson, S. R., & Davis, M. E. (2017). Best practices for non-destructive testing of cast aluminum components in automotive industries. SAE Technical Paper 2017-01-1698.

6. Lee, H. W., & Park, J. S. (2022). Recent advancements in portable analytical techniques for on-site material verification of cast aluminum parts. Spectrochimica Acta Part B: Atomic Spectroscopy, 188, 106378.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions