How to Ensure Quality in Cast Iron Components: A Buyer’s Checklist?

Since of its moo fetched, long life expectancy, and versatility, cast press components discover broad utilization in a assortment of segments, counting development and car. You must ensure that these components are of great quality if you want them to operate well and last a long time. Having a thorough checklist to assess the quality of cast iron components is crucial for buyers. Read this blog article to learn about the most critical considerations, typical flaws to look out for, and questions to ask your supplier. Obtaining high-quality cast iron components that match your unique needs will be much easier if you follow this buyer's checklist. Anybody, in any case of expertise level, may advantage from this book's informational on how to effectively secure cast press.

Key Quality Indicators to Look for When Buying Cast Iron Components

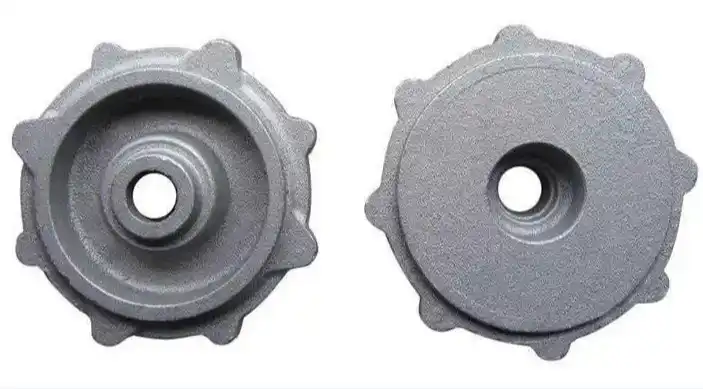

Surface Finish and Appearance

The surface finish and appearance of cast iron components are critical indicators of their overall quality. A smooth, uniform surface without visible defects is generally a sign of good casting practices. When inspecting cast iron components, look for a consistent color and texture across the entire surface. High-quality cast iron should have a uniform gray appearance without discoloration or mottling. Pay close attention to any signs of porosity, which may appear as small pits or holes on the surface. These imperfections can significantly impact the component's strength and performance. Additionally, check for any visible cracks, seams, or cold shuts, which are defects that occur when two streams of molten metal fail to fuse properly during the casting process. A clean, well-defined surface with sharp edges and smooth curves indicates precision in the casting process and proper finishing techniques.

Dimensional Accuracy and Tolerances

Dimensional accuracy is crucial for ensuring that cast iron components fit and function as intended within their respective assemblies. When evaluating cast iron parts, use precise measuring tools to verify that all dimensions meet the specified tolerances. Pay particular attention to critical dimensions that affect the component's functionality or its ability to interface with other parts. High-quality cast iron components should consistently meet or exceed the required dimensional tolerances across multiple production batches. The dimensional accuracy of a product may be affected by various post-casting procedures and casting techniques. When contrasted with investment casting and machined components, sand casting's tolerances may be more lenient. Make that the supplier's stated tolerances are in line with your application-specific needs by discussing them with them. To ensure consistency and find process control concerns, it's a good idea to measure many pieces from the same manufacturing run as a sample.

Material Composition and Microstructure

The mechanical characteristics and overall performance of cast iron components are heavily influenced by their material composition and microstructure. You should ask your supplier for material certifications that list the exact chemical make-up of the cast iron, including the amounts of carbon, silicon, manganese, and any alloying components. A component's strength, toughness, and wear resistance are heavily affected by its exact composition. If the material is to be used for anything significant, it should be evaluated independently to ensure it meets all specifications. Metallography and other forms of microstructural examination may tell us a lot about the cast iron's quality. When examining gray iron or ductile iron, make sure the graphite flakes or nodules are evenly distributed. The material's characteristics are significantly impacted by the dimensions, geometry, and dispersion of these graphite structures. You should also look at the graphite's matrix structure; it might be pearlitic, ferritic, or a mix of the two, and each kind has its own set of advantages and disadvantages that make it useful in different contexts.

Common Defects in Cast Iron and How to Identify Them Before Purchase?

Porosity and Inclusions

Porosity and inclusions are among the most common defects found in cast iron components, and they can significantly impact the part's structural integrity and performance. Porosity refers to the presence of small voids or cavities within the casting, which can occur due to gas entrapment during the solidification process or shrinkage as the metal cools. These flaws may be seen visually as tiny holes on the surface, or they can be detected via non-destructive testing procedures like ultrasound or radiography. The cast iron matrix, on the other hand, contains impurities and foreign particles known as inclusions. The casting process incorporates a variety of impurities, including slag particles, mold sand, and others. Premature failure may result from inclusions weakening the material and creating stress concentration areas. Get comprehensive inspection reports, including findings from non-destructive testing, from your supplier before you buy to find these flaws. If possible, conduct your own visual and tactile inspections of sample parts, paying close attention to any irregularities in surface texture or unexpected variations in weight.

Cracks and Cold Shuts

Cracks and cold shuts are serious defects that can compromise the structural integrity of cast iron components. Thermal stress during cooling, poor mold design, and handling concerns are among the many potential causes of cracks. Depending on the casting, they could be out in the open or concealed. A cold shut, often called a cold lap, is a casting flaw that happens when two streams of molten metal don't mix well enough when pouring. In order to spot these flaws, you need to visually check the cast iron parts in well-lit areas. Keep an eye out for fissures that could be indicated by linear patterns on the surface. Cold shuts are surface features that seem like lines or seams and may be somewhat different in color or texture from the rest of the surface. Dye penetrant testing and magnetic particle inspection are two examples of non-destructive testing procedures that might be used for more thorough detection. Surface and near-surface flaws that can be invisible to the human eye can be detected using these methods. When inspecting complex geometries or internal features, X-ray or CT scanning may be necessary to identify hidden cracks or cold shuts.

Dimensional Inconsistencies and Warping

Dimensional inconsistencies and warping are defects that can significantly affect the functionality and fit of cast iron components within larger assemblies. These issues can arise from various factors, including improper mold design, uneven cooling rates, or inadequate process control during casting. Dimensional inconsistencies may manifest as variations in wall thickness, overall dimensions, or the positioning of critical features. Warping, on the other hand, refers to the distortion of the component from its intended shape, often resulting in bends, twists, or other deviations from the specified geometry. To identify these defects before purchase, it's essential to conduct thorough dimensional inspections using precise measuring tools such as calipers, micrometers, and coordinate measuring machines (CMMs). Compare the measured dimensions against the provided technical drawings or 3D models, paying particular attention to critical dimensions and tolerances. For complex geometries, consider using 3D scanning technology to create a digital model of the actual part, which can then be compared to the original design to identify any deviations. Additionally, inspect the component for any visible signs of warping, such as gaps when placed on a flat surface or misalignment of mating surfaces.

Essential Questions to Ask Your Cast Iron Supplier for Quality Assurance

Production Process and Quality Control Measures

Understanding the production process and quality control measures implemented by your cast iron supplier is crucial for ensuring consistently high-quality components. Ask specific inquiries on the furnaces utilized, melting procedures, and pouring processes to get a feel for their casting methods. Find out how they make the molds and whether they treat the sand or any of the other materials used to make the molds in any way to make them more smooth and less prone to flaws. Get to know their process control procedures, which include keeping an eye on and adjusting things like pouring speed, cooling rates, and melt temperature. Ask about their quality control procedures at each stage of production, from raw material inspection to final product testing. Do they employ statistical process control (SPC) methods to monitor and improve their casting processes? What kind of in-process inspections do they perform, and how do they handle non-conforming parts? If you want your cast iron components to have the mechanical qualities you want, you need find out what they can do with heat treatment and how they do it. Gaining insight into these parts of their manufacturing process will help you understand the supplier's dedication to quality and their capacity to reliably create cast iron components of high quality.

Material Testing and Certification Practices

To ensure high quality, cast iron components must undergo testing and certification. Inquire about the supplier's material testing techniques and frequency as a first step in addressing these concerns. Are chemical analyses conducted on a regular basis to verify that the cast iron's composition is up to par? Get the lowdown on the mechanical testing procedures they use, including tensile, hardness, and impact tests. Are samples taken from each production run or are these tests done periodically? If so, how often are they run? Knowing what they can do in terms of metallurgical analysis is also crucial. Do they do microstructural analysis in-house or use a third party? Inquire about the techniques used to discover interior faults using non-destructive testing, including radiography, ultrasonic testing, and magnetic particle inspection. Regarding certification, inquire about the types of material certificates they provide and whether these comply with relevant industry standards such as EN 10204. Can they provide full traceability for the raw materials used in their castings? Additionally, ask about their quality management system certifications, such as ISO 9001, and any industry-specific certifications they may hold. Understanding their material testing and certification practices will help you assess the reliability and consistency of their cast iron components.

Handling of Non-Conformities and Continuous Improvement Efforts

You can tell a lot about a cast iron supplier's dedication to quality and customer happiness by how they deal with non-conformities and how they approach continuous improvement. First things first: find out how they deal with non-conforming items. When a problem with quality or a fault is found, what do they do? Find out how they identify the source of problems and how they fix them so that quality problems don't happen again. The way they deal with customer feedback and complaints should also be carefully considered. How is their response time to quality concerns from customers and what is their typical process for resolving these issues? Get to the bottom of whether they intend to gradually improve their processes and whether they incorporate feedback from past errors into their decision-making process. Is there a set procedure for gathering and evaluating high-quality data in order to spot patterns and areas for growth? Inquire about the company's recent expenditures in new technology or process changes that seek to increase product quality. Because the quality of the raw materials has such a profound effect on the finished product, you should also inquire about their supplier management policies. How do they vet and keep tabs on their own vendors to guarantee constant quality in their products? Gain trust in their capacity to sustainably increase the quality of their cast iron components by familiarizing yourself with their approach to non-conformities and continual improvement.

Conclusion

A number of aspects must be carefully considered in order to ensure quality in cast iron components. If you follow this buyer's criteria, you'll have a much easier time finding high-quality cast iron parts that fit your needs. Keep an eye out for typical flaws like porosity, fractures, and warping, and be sure to check the material composition, surface polish, and dimensional correctness. If you want your relationship with your supplier to succeed, you must communicate openly with them about their manufacturing methods, quality control procedures, and attempts at continual development. You can make sure your finished goods are reliable and work well by following these tactics, which will also reduce the likelihood of acquiring low-quality components.

For those seeking a reliable partner in cast iron component procurement, Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. offers a comprehensive range of services. Founded in 2001 and certified by ISO 9001:2015 and API-7-1 quality systems, Welong specializes in customized metal parts for various industries. They have extensive experience with machining, iron casting, steel, stainless steel, aluminum, copper, zinc, and sand casting, among other processes. Timely delivery, quality control, and manufacturing process improvement are all helped along by their expert engineers and personnel. In the field of international supply chain management, Welong aspires to remain at the forefront via its dedication to innovation and worldwide presence. For more information or inquiries, please contact them at info@welongpost.com.

References

1. Smith, J. R. (2018). "Quality Control in Cast Iron Production: A Comprehensive Guide." Journal of Foundry Engineering, 42(3), 156-172.

2. Johnson, A. L., & Brown, T. E. (2019). "Defect Detection and Prevention in Cast Iron Components." Materials Science and Engineering: A, 745, 281-295.

3. Williams, M. K. (2020). "Advanced Techniques for Cast Iron Microstructure Analysis." Metallurgical and Materials Transactions A, 51(8), 3956-3970.

4. Thompson, R. D., et al. (2017). "Dimensional Accuracy in Cast Iron: Challenges and Solutions." International Journal of Metalcasting, 11(3), 528-540.

5. Davis, E. S. (2021). "Supplier Quality Management in the Cast Iron Industry." Quality Engineering, 33(2), 215-229.

6. Lee, H. W., & Chen, Y. T. (2018). "Continuous Improvement Strategies for Cast Iron Foundries." Journal of Manufacturing Processes, 36, 175-188.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions