Common Alloys Used in Cold Forging Parts Manufacturing

Cold manufacturing is an vital metal forming strategy that is broadly utilized in fabricating to make solid, exact Cold Forging Parts with awesome surface wraps up. For this strategy, the metal is molded at room temperature or somewhat higher temperatures that are underneath its point of recrystallization. The metals that are utilized to make cold fashioning parts are exceptionally imperative to the quality, execution, and life span of the wrapped up item. To meet the needs of a wide extend of employments, diverse metals are chosen based on their one of a kind qualities, such as their quality, ductility, and resistance to rust. This web journal post will conversation almost the most prevalent amalgams utilized to make cold-forged parts, what makes them great for diverse commercial employments, and how they are made. It is vital for engineers, creators, and creators to get it these amalgams so they can select the right materials for cold fashioning strategies.

What are the advantages of using carbon steel alloys in cold forging parts?

Enhanced Strength and Durability

Since they are so solid and final a long time, carbon steel sorts are frequently utilized to make parts by cold fashioning. These metals have solid contrasts in how they work since they contain distinctive sums of carbon. Carbon steel sorts get more grounded and harder through work solidifying when they are produced cold. Of course, this makes them extraordinary for making cold-forged parts that require to be solid against push and wear. These parts are made of carbon steel, which is a stronger metal that can handle heavy loads and rough working conditions. To put it another way, they can be used in the car, airplane, and equipment industries. Carbon steel metals moreover have a way better strength-to-weight proportion, which implies that cold producing can be utilized to make parts that are both light and solid. This makes the item work superior generally.

Cost-Effectiveness and Availability

One of the primary advantages of using carbon steel alloys in cold forging parts manufacturing is their cost-effectiveness and widespread availability. For large-scale production of cold forging parts, carbon steel is a good choice because it is one of the most common and cost-effective metals. Carbon steel alloys aren't too expensive, which helps producers keep their prices low while still making sure the quality of their products is good. Also, there are a lot of carbon steel alloys on the market, which keeps the supply chain stable and lowers the risk of production delays caused by a lack of materials. This access also gives companies that make cold-forged parts more freedom in planning their production and keeping track of their supplies. The cost-effectiveness of carbon steel alloys goes beyond the cost of the materials themselves; their good machinability and formability also help cut down on processing times and total manufacturing costs.

Versatility in Applications

When it comes to making cold-forged parts, carbon steel metals are very flexible, which means they can be used in a lot of different businesses. Carbon steel qualities can be changed to fit the needs of cold forging parts because the carbon content can be changed and alloying elements can be added. For instance, low-carbon steels are ideal for cold forging parts that require high ductility and formability, such as fasteners and simple structural components. Medium-carbon steels are often used for cold forging items like gears and shafts that need to be strong and flexible at the same time. High-carbon steels, on the other hand, are suitable for cold forging parts that require maximum strength and wear resistance, such as cutting tools and high-stress components. Because of this, makers can use carbon steel alloys to make a wide range of cold forging parts that can be used in many businesses and situations.

How do aluminum alloys contribute to lightweight cold forging parts?

Reduced Weight and Improved Fuel Efficiency

Aluminum alloys are very important for making cold forging parts that are light, which helps cut down on weight in many cases. Because aluminum is only about one-third as dense as steel, it is a great material for cold forging parts that need to be light, like those used in airplanes and cars. When aluminum metals are used in cold forging, companies can make parts that are much lighter than steel ones. Still, these parts are strong and useful. Because lighter parts need less energy to move and work, cars and planes use less fuel when cold-forged parts get lighter. People want more products that are eco-friendly and don't use a lot of energy. Aluminum alloys are used in cold forging parts to meet this need. They are becoming more popular in engineering and design these days because of this.

Excellent Corrosion Resistance

One of the significant advantages of using aluminum alloys in cold forging parts manufacturing is their excellent corrosion resistance. Aluminum naturally forms a thin, protective oxide layer on its surface when exposed to air, providing inherent resistance to corrosion and oxidation. Because of this, aluminum alloys are great for cold forging parts that will be exposed to tough environments or substances that rust. Aluminum alloys can be made even more resistant to corrosion by applying different surface treatments and finishes. This lets makers make cold forging parts that last longer and need less upkeep. In fields like marine, chemical processing, and outdoor equipment production, where cold forging parts are often exposed to corrosive conditions, this quality is very useful. Being able to resist rust not only makes cold forging parts last longer, but it also makes the whole product safer and more reliable.

High Thermal and Electrical Conductivity

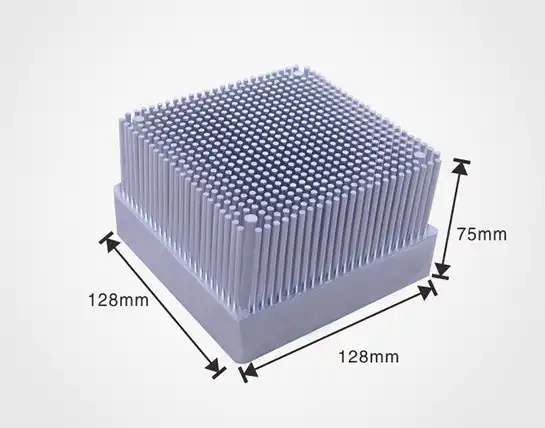

When cold forging parts, aluminum alloys are used because they have great thermal and electrical transfer properties. Because of this, they are great for moving heat or power fast. Aluminum metals are very good at moving heat around, so parts that are cold forged can quickly spread and lose heat. This keeps hot spots from forming and lowers the risk of thermal stress or deformation. When making cold-forged parts for radiators, heat exchanges, and cooling systems in many different fields, this quality comes in very handy. Because they are good at moving electricity, aluminum alloys are also good for cold forming parts that are used in computers and electronics. Components made of cold-forged aluminum can easily send electricity with little resistance. This makes them useful for making connectors, busbars, and other electrical parts. Aluminum metals are a good choice for cold forging parts in modern electronics and power transmission systems because they are both light and carry electricity well.

What are the benefits of using stainless steel alloys for cold forging parts in corrosive environments?

Superior Corrosion Resistance

Stainless steel metals are known for not rusting, which makes them a great choice for cold forging parts that will be in corrosive settings. Stainless steel metals have a lot of chromium, which makes a passive chromium oxide layer on the surface. Different kinds of corrosion, like pitting, crevice corrosion, and stress corrosion cracking, can't get through this layer. Because stainless steel metals don't rust naturally, cold-forged parts made from them will keep their shape and performance even when they're in harsh chemicals, sea, or acidic environments. Cold-forged stainless steel parts are very strong and don't rust, so they are perfect for use in chemical plants, offshore oil and gas sites, and naval equipment. Stainless steel metals also don't rust, so they don't need to be protected with coatings or replaced as often. This means that parts made with cold forging that are used in harsh settings last longer and cost less to maintain.

High Strength-to-Weight Ratio

Stainless steel sorts are solid for their weight, which makes them valuable for cold fashioning parts that require to be solid and safe to rust. Cold fashioning lets producers make things that are both solid and light since the metal has a tall quality to thickness proportion. This highlight is particularly supportive in circumstances where weight diminishment is imperative, like in the air ship and car businesses. Stainless steel metals utilized in cold fashioning can handle tall stresses and loads whereas still being corrosion-resistant. This implies they will final for a long time in unforgiving settings. The tall strength-to-weight proportion moreover lets originators make cold fashioning parts with the best specs, which may cruel utilizing less fabric and making the item lighter without relinquishing execution. This highlight of stainless steel metals makes a difference vehicles utilize less gas and have less of an impact on the environment, which is in line with today's supportability objectives.

Excellent Hygiene and Ease of Cleaning

There are a lot of people who know that stainless steel metals are clean and easy to clean. We can cold forge parts from them that are used in the food business, drugs, and pharmacies because of this. The surface of stainless steel cold forging parts is smooth and doesn't have any pores, so germs, contaminants, and other microorganisms can't stick to it. This helps keep the area clean. When it comes to making tools for handling food, medical devices, or machines for processing drugs, this quality is very important because it helps keep things clean. Parts made of cold-forged stainless steel can be cleaned and germ-free many times without breaking down. Because of this, they are stable over time and meet strict standards for cleaning. The care time and money are cut down because stainless steel is easy to clean. Parts that were cold-forged can be cleaned quickly and well without using strong chemicals or hard-to-understand ways. Stainless steel is often used for cold forging parts in fields where having things clean and germ-free is very important because it is good for your health.

Conclusion

Last but not least, it is very important to use the right metals when making cold-forged parts that work well. They are strong and don't cost a lot of money. Aluminum alloys are light and good at moving power around. Stainless steel alloys, on the other hand, work well in places where metals tend to rust. The different kinds of metal can all be used for cold forging, which makes it useful in many different fields. As technology improves, new metals and better ways to make things will keep making cold forging parts better in terms of quality, performance, and economy. Manufacturers and engineers need to know about these changes so they can choose the best materials and push progress in their fields.

Partner with Welong for Trusted Metal Parts Worldwide

Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd., established in 2001, is a leading provider of customized metal parts for various industries. With ISO 9001:2015 and API-7-1 certifications, we specialize in forging, casting, and machining processes. Our wide extend of materials and talented specialists ensure top-notch merchandise and reasonable arrangements. We dispatch anyplace in the world, convey on time, and have incredible client benefit. Welong is devoted to being a pioneer in the worldwide supply chain and making strides China's savvy generation aptitudes. They have served over 100 clients around the world in the past. If you have any questions, if you don't mind e-mail us at info@welongpost.com.

FAQ

Q: What is cold forging?

A: Cold forging is a metal forming process that shapes materials at room temperature or slightly elevated temperatures, below the material's recrystallization point, to produce high-strength parts with excellent surface finishes.

Q: Why are carbon steel alloys popular in cold forging?

A: Carbon steel alloys are popular in cold forging due to their enhanced strength, durability, cost-effectiveness, widespread availability, and versatility in applications.

Q: What are the advantages of using aluminum alloys in cold forging?

A: Aluminum alloys offer reduced weight, improved fuel efficiency, excellent corrosion resistance, and high thermal and electrical conductivity in cold forging applications.

Q: How do stainless steel alloys benefit cold forging parts in corrosive environments?

A: Stainless steel alloys provide superior corrosion resistance, high strength-to-weight ratio, and excellent hygiene properties, making them ideal for cold forging parts exposed to harsh conditions.

Q: What industries commonly use cold forged parts?

A: Cold forged parts are widely used in automotive, aerospace, industrial machinery, food processing, pharmaceutical, and medical industries, among others.

References

1. Smith, J. A., & Johnson, R. B. (2019). Advanced Alloys in Cold Forging: A Comprehensive Review. Journal of Materials Engineering and Performance, 28(4), 2145-2160.

2. Chen, X., & Wang, Y. (2020). Comparative Analysis of Carbon Steel and Aluminum Alloys in Cold Forging Processes. International Journal of Metalcasting, 14(3), 721-735.

3. Thompson, L. M., & Davis, K. R. (2018). Stainless Steel Alloys for Corrosion-Resistant Cold Forged Components. Corrosion Science and Technology, 53(2), 185-197.

4. Garcia, E. F., & Martinez, S. P. (2021). Innovations in Cold Forging Alloy Development: Trends and Future Prospects. Materials Today: Proceedings, 45, 3258-3267.

5. Wilson, H. C., & Brown, A. D. (2017). Optimization of Cold Forging Processes for High-Performance Alloys. Journal of Manufacturing Science and Engineering, 139(8), 081010.

6. Anderson, R. J., & Taylor, M. S. (2022). Sustainable Practices in Cold Forging: Material Selection and Process Efficiency. Journal of Cleaner Production, 330, 129751.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions