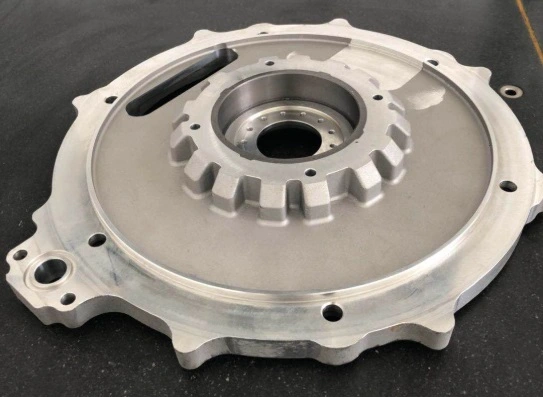

Aluminum Casting Defects: Causes, Prevention, and Inspection Tips

Aluminum casting is a widely used manufacturing process that offers numerous advantages, including lightweight components, excellent corrosion resistance, and cost-effectiveness. However, like any manufacturing process, aluminum casting is not without its challenges. Defects can occur during the casting process, potentially compromising the quality, performance, and reliability of the final product. Understanding these defects, their causes, and how to prevent them is crucial for manufacturers and quality control professionals in the aluminum casting industry. This comprehensive blog post will delve into the most common aluminum casting defects, explore strategies for prevention, and provide valuable inspection tips to ensure the production of high-quality aluminum cast parts.

What Are the Most Common Defects in Aluminum Casting?

Porosity

Porosity is one of the most prevalent defects in aluminum casting, characterized by the presence of small voids or cavities within the cast part. These voids can significantly impact the mechanical properties and structural integrity of the final product. In aluminum casting, porosity can occur due to several factors, including gas entrapment during the pouring process, shrinkage during solidification, or the presence of hydrogen in the molten metal. Gas porosity typically results in rounded, smooth-walled pores, while shrinkage porosity often appears as irregularly shaped voids. To mitigate porosity in aluminum casting, manufacturers must carefully control the metal composition, melting temperature, and pouring techniques. Proper degassing of the molten aluminum and optimizing the gating and risering system can also help reduce the occurrence of porosity defects.

Cold Shuts

Cold shuts are defects that occur when two streams of molten metal meet but fail to fuse properly, resulting in a visible line or seam in the cast part. This defect is particularly common in aluminum casting due to the metal's relatively low melting point and tendency to cool quickly. Cold shuts can significantly compromise the strength and integrity of the cast part, potentially leading to premature failure. To prevent cold shuts in aluminum casting, it is crucial to maintain an adequate pouring temperature and ensure a consistent flow of molten metal into the mold. Proper gating design and the use of chills or insulation in critical areas of the mold can help promote uniform solidification and reduce the likelihood of cold shut formation. Additionally, optimizing the mold filling rate and considering the use of vacuum-assisted casting techniques can further mitigate the risk of cold shuts in aluminum castings.

Hot Tears

Hot tears, also known as hot cracks, are a type of defect that occurs during the solidification process of aluminum casting. These defects manifest as irregular, jagged cracks that form when the partially solidified metal is subjected to excessive tensile stress. Hot tears are particularly problematic in aluminum alloys with a wide freezing range, as these materials are more susceptible to stress buildup during solidification. The consequences of hot tears can be severe, as they significantly compromise the structural integrity and mechanical properties of the cast part. To prevent hot tears in aluminum casting, manufacturers must carefully control the alloy composition, mold design, and cooling rates. Implementing proper gating and risering systems can help ensure uniform solidification and reduce the risk of hot tear formation. Additionally, optimizing the casting process parameters, such as pouring temperature and mold preheating, can contribute to minimizing the occurrence of hot tears in aluminum castings.

How to Identify and Prevent Casting Defects in Aluminum Parts?

Visual Inspection Techniques

Visual inspection is a fundamental and cost-effective method for identifying casting defects in aluminum parts. This technique involves carefully examining the surface of the cast component for visible imperfections such as cracks, porosity, or surface irregularities. In aluminum casting, visual inspection can be particularly effective in detecting defects like cold shuts, misruns, and surface porosity. To enhance the effectiveness of visual inspection, proper lighting and magnification tools should be used. Additionally, training inspectors to recognize specific defect patterns and characteristics unique to aluminum casting can significantly improve the accuracy of visual inspections. While visual inspection is an essential first step in quality control, it is important to note that it may not detect internal defects or subtle imperfections. Therefore, visual inspection should be complemented with other non-destructive testing methods to ensure comprehensive quality assurance in aluminum casting production.

Non-Destructive Testing Methods

Non-destructive testing (NDT) methods play a crucial role in identifying and preventing casting defects in aluminum parts without compromising the integrity of the component. Several NDT techniques are particularly effective for aluminum casting inspection. Radiographic testing, using X-rays or gamma rays, can reveal internal defects such as porosity, inclusions, and cracks that may not be visible on the surface. Ultrasonic testing is another valuable method for detecting internal flaws in aluminum castings, especially in thick-walled components. Dye penetrant testing is highly effective for identifying surface-breaking defects in aluminum castings, such as cracks and porosity. Eddy current testing can be used to detect surface and near-surface defects in aluminum castings, particularly in thin-walled components. By employing a combination of these NDT methods, manufacturers can significantly enhance their ability to identify and prevent casting defects in aluminum parts, ensuring higher quality and reliability of the final products.

Process Control and Optimization

Effective process control and optimization are essential for preventing casting defects in aluminum parts. This approach involves carefully monitoring and adjusting various parameters throughout the casting process to minimize the risk of defect formation. In aluminum casting, key process variables that require close attention include metal composition, melting temperature, pouring rate, and cooling conditions. Implementing robust statistical process control (SPC) techniques can help identify trends and variations in these parameters, allowing for timely adjustments to maintain optimal casting conditions. Additionally, the use of advanced simulation software for mold filling and solidification analysis can provide valuable insights into potential defect formation areas, enabling proactive design modifications. Continuous improvement initiatives, such as Six Sigma methodologies, can further enhance the overall quality and efficiency of the aluminum casting process. By focusing on process control and optimization, manufacturers can significantly reduce the occurrence of casting defects in aluminum parts and improve overall product quality.

Inspection Techniques for Ensuring Quality in Aluminum Casting

Dimensional Measurement and Tolerancing

Dimensional measurement and tolerancing are critical aspects of quality assurance in aluminum casting. Accurate dimensional control ensures that cast parts meet the specified design requirements and function properly in their intended applications. In aluminum casting, dimensional variations can occur due to factors such as shrinkage, mold deformation, or improper gating and risering. To ensure dimensional accuracy, manufacturers employ a range of measurement techniques, including coordinate measuring machines (CMMs), optical comparators, and 3D scanning systems. These tools allow for precise measurement of critical dimensions, geometries, and surface profiles of aluminum castings. Implementing geometric dimensioning and tolerancing (GD&T) principles in the design and inspection process can further enhance the ability to control and verify critical features of aluminum cast parts. By establishing clear dimensional tolerances and employing advanced measurement techniques, manufacturers can ensure consistent quality and interchangeability of aluminum castings across production runs.

Metallurgical Analysis

Metallurgical analysis is a crucial inspection technique for ensuring the quality and integrity of aluminum castings. This approach involves examining the microstructure, composition, and properties of the cast material to verify compliance with specifications and identify potential defects or material-related issues. In aluminum casting, metallurgical analysis typically includes techniques such as optical microscopy, scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDS). These methods allow for detailed examination of grain structure, dendrite arm spacing, and the presence of intermetallic compounds or inclusions that may affect the mechanical properties of the casting. Additionally, chemical analysis techniques like optical emission spectroscopy (OES) or X-ray fluorescence (XRF) can be used to verify the elemental composition of the aluminum alloy. Hardness testing and tensile testing are also commonly performed to assess the mechanical properties of the cast material. By conducting thorough metallurgical analysis, manufacturers can ensure that aluminum castings meet the required material specifications and maintain consistent quality across production batches.

Performance Testing and Validation

Performance testing and validation are essential steps in ensuring the quality and reliability of aluminum castings in their intended applications. This process involves subjecting the cast parts to simulated or actual operating conditions to verify their functional performance and durability. In aluminum casting, performance testing may include pressure testing for components designed to contain fluids or gases, fatigue testing to assess long-term durability under cyclic loading, and impact testing to evaluate resistance to sudden loads or shocks. Thermal cycling tests may be conducted to assess the behavior of aluminum castings in applications with varying temperature conditions. Corrosion resistance testing is also crucial for many aluminum casting applications, particularly in automotive or marine environments. Additionally, non-destructive evaluation techniques such as acoustic emission testing can be employed to monitor the behavior of aluminum castings under load and detect potential defects or failure modes. By conducting comprehensive performance testing and validation, manufacturers can ensure that aluminum castings meet the required functional specifications and perform reliably in their intended applications.

Conclusion

Aluminum casting defects pose significant challenges to manufacturers, but with proper understanding, prevention strategies, and inspection techniques, these issues can be effectively managed. By implementing robust quality control measures, optimizing process parameters, and utilizing advanced inspection technologies, manufacturers can consistently produce high-quality aluminum castings. The key to success lies in a comprehensive approach that combines proactive defect prevention with thorough inspection and testing protocols. As the demand for lightweight, durable aluminum components continues to grow across various industries, the importance of mastering defect management in aluminum casting cannot be overstated. By staying informed about the latest advancements in casting technologies and quality assurance methods, manufacturers can maintain a competitive edge in the ever-evolving field of aluminum casting.

For expert assistance in aluminum casting and quality control, consider partnering with Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd. Founded in 2001 and certified by ISO 9001:2015 and API-7-1 quality systems, Welong specializes in the development and supply of customized metal parts for various industries. With capabilities in forging, sand casting, investment casting, centrifugal casting, and machining, Welong offers a comprehensive range of services to meet your aluminum casting needs. Their experienced staff and engineers can help optimize production processes, control quality, and ensure timely delivery. With a global presence and a commitment to excellence, Welong is dedicated to helping customers succeed in their aluminum casting projects. For more information, contact them at info@welongpost.com.

References

1. Campbell, J. (2015). Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design. Butterworth-Heinemann.

2. Kaufman, J. G., & Rooy, E. L. (2004). Aluminum Alloy Castings: Properties, Processes, and Applications. ASM International.

3. Lumley, R. (2018). Fundamentals of Aluminium Metallurgy: Recent Advances. Woodhead Publishing.

4. Sholapurwalla, S., & Maniar, N. (2019). Aluminum Casting Technology. American Foundry Society.

5. Sabau, A. S., & Viswanathan, S. (2016). Microstructural Evolution During Solidification of Aluminum Alloys: Simulation and Experiment. Springer.

6. Warmuzek, M. (2004). Aluminum-Silicon Casting Alloys: Atlas of Microfractographs. ASM International.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions