Aluminium Casting Part or Medical Spare Parts? Best Choice for Asia’s Needs

In the rapidly evolving landscape of Asia's industrial and medical sectors, the choice between aluminium casting parts and medical spare parts has become increasingly crucial. As the region continues to experience unprecedented growth and technological advancement, manufacturers and healthcare providers are faced with the challenge of selecting the most suitable components for their specific needs. This blog explores the merits of aluminium casting parts and medical spare parts, delving into their respective advantages, applications, and potential impact on Asia's diverse industries. By examining factors such as durability, cost-effectiveness, versatility, and sustainability, we aim to provide valuable insights to help decision-makers make informed choices that align with their unique requirements and the region's dynamic market demands.

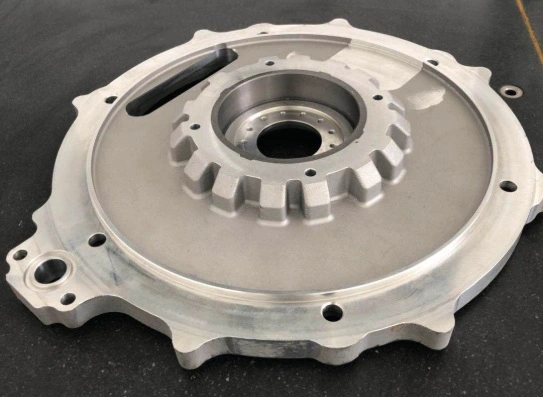

What are the advantages of aluminium casting parts in Asian manufacturing?

Lightweight and Corrosion-Resistant Properties

Due to their light weight and great resistance to corrosion, aluminum casting parts have big benefits in Asian production. Because of these qualities, aluminum casting parts are great for many things, such as cars, ships, and market goods. Less metal means less weight, which means better gas mileage in cars and faster flight in planes. Also, metal casting parts won't rust, so they will last a long time and work well, even in harsh places like many Asian countries. When makers in the area use aluminum casting parts, they can save money on maintenance costs and make their goods last longer because they are strong.

Cost-Effective Production and Scalability

The cost-effectiveness of aluminium casting parts is a crucial factor driving their popularity in Asian manufacturing. When you cast metal, you can make complicated shapes and patterns with little waste. This means that it costs less to make than other ways. This speed helps Asian businesses that want to make their work better while keeping their prices low enough to fight on the world market. Also, aluminum casting parts are very scalable, which means that makers can easily change the amount of production to meet changing demand. In Asia's lively and fast-paced industrial environment, where market conditions can change quickly, this kind of adaptation is very important.

Versatility and Customization Options

It is easy to change aluminum casting parts in a lot of different ways, which makes them a great choice for many uses in Asian businesses. With the aluminum casting method, parts can be made with complicated forms and accurate measures. This lets people make parts that are just right for their needs. Because of this, it is very useful in areas like telecommunications that need small, complicated forms. Another easy way to change or improve aluminum casting parts is to add different surface finishes and treatments. Now they're even better. Asian manufacturers are better at both home and abroad because they can change the way metal casting parts look and work to suit different needs.

How do aluminium casting parts contribute to sustainability in Asian industries?

Energy-Efficient Manufacturing Process

Because they are made in a way that uses little energy, aluminum casting parts are a big part of making Asian businesses more environmentally friendly. Making aluminum casting parts uses less energy than many other ways of making metal products, which means they leave less of a carbon footprint. It fits in with the growing focus on eco-friendly methods in Asian countries, where governments and companies are paying more attention to protecting the environment. By using metal casting parts, manufacturers can save energy and show that they care about using eco-friendly ways to make things. It costs less to make aluminum because it takes less energy. It's a good choice for companies that want to make money and help the world at the same time.

Recyclability and Circular Economy Potential

One of the most significant sustainability benefits of aluminium casting parts is their high recyclability, which aligns perfectly with the principles of a circular economy. Aluminum can be recycled over and over again without losing any of its properties. Because of this, it's a great medium for Asian companies that want to be green in the long run. Reusing aluminum casting parts only takes a small amount of the energy that is needed to make new aluminum, which is even better for the earth. This ability to be recycled not only saves natural resources but also cuts down on trash, which are two very important environmental issues in Asian countries that are industrializing quickly. Asian makers can help close the loop on material use and make the industrial environment more sustainable by adding aluminum casting parts to their goods.

Longevity and Reduced Replacement Frequency

The durability and longevity of aluminium casting parts significantly contribute to sustainability in Asian industries by reducing the frequency of replacements and repairs. Due to their corrosion resistance and structural integrity, aluminium casting parts often outlast components made from alternative materials, especially in challenging environmental conditions common in many Asian regions. This longer life means that fewer resources are needed to make replacements, and less trash is made over time. Because parts don't have to be replaced as often, there is less downtime in factories, which boosts productivity and efficiency. By choosing aluminium casting parts, Asian manufacturers can create products with longer lifespans, aligning with the growing consumer demand for durable and sustainable goods while simultaneously reducing the overall environmental impact of their industries.

What are the key applications of aluminium casting parts in Asia's emerging technologies?

Electric Vehicle Components

Casting parts made of aluminum are very important to the electric vehicle (EV) business in Asia, which is growing very quickly. As China, Japan, and South Korea lead the way in making and using electric vehicles, the need for parts that are light, durable, and efficient has grown. Casting parts made of aluminum are often used in EV battery housings, motor cases, and structural parts because they are good at managing heat and keeping things light. Since EVs are made with parts cast in metal, they have longer ranges, faster speeds, and more safety features. In this area, the metal casting business will grow a lot as long as Asian countries keep giving people reasons to buy and use electric cars (EVs). This will help the car business think of new ways to help the environment.

5G Infrastructure and Telecommunications

The rollout of 5G networks across Asia has created a substantial demand for aluminium casting parts in telecommunications infrastructure. Aluminum is a great material for 5G base stations, antennas, and other network parts because it conducts heat well and blocks electromagnetic waves (EMI). Because aluminum casting parts are light, they also make it easier to set up and maintain telecoms equipment, which is especially helpful in cities where room is limited. As Asian countries rush to set up full 5G service, the need for aluminum casting parts in this industry is likely to grow by a huge amount. Because aluminum casting methods are precise and can be customized, they can make the complicated shapes and designs needed for modern telecoms equipment. In a field that changes so quickly, this makes them even more important.

Smart City Technologies and IoT Devices

Aluminium casting parts are becoming increasingly crucial in the development of smart city technologies and Internet of Things (IoT) devices across Asia. As cities in places like Singapore, South Korea, and India adopt smart city plans, the need for long-lasting, efficient, and internet-connected parts has gone through the roof. Because they are good at getting rid of heat and being resistant to environmental factors, aluminum casting parts are used in a lot of smart lighting systems, traffic control devices, environmental sensors, and other IoT tools. The versatility of aluminium casting allows for the integration of complex electronic components within sleek, weather-resistant housings, making it ideal for outdoor smart city applications. As Asia continues to lead in smart city development and IoT innovation, the role of aluminium casting parts in shaping the future of urban living and connectivity is set to expand significantly.

Conclusion

In conclusion, aluminium casting parts emerge as a compelling choice for Asia's diverse industrial needs, offering a unique combination of lightweight properties, corrosion resistance, cost-effectiveness, and sustainability. Their versatility and customization potential make them ideal for applications ranging from electric vehicles to 5G infrastructure and smart city technologies. As Asia continues to drive global innovation and industrial growth, the adoption of aluminium casting parts is likely to accelerate, contributing to enhanced efficiency, reduced environmental impact, and improved product performance across various sectors. While medical spare parts remain crucial in healthcare, the widespread applicability and benefits of aluminium casting parts position them as a key enabler of Asia's technological advancement and sustainable industrial future.

Trust Welong for Custom Metal Parts & Global Supply Chain Solutions

Shaanxi Welong Int'l Supply Chain Mgt Co.,Ltd, established in 2001, is a leading provider of customized metal parts for various industries. With certifications including ISO 9001:2015 and API-7-1, we specialize in forging, sand casting, investment casting, centrifugal casting, and machining. Our expertise spans a wide range of materials, including iron cast, steel, stainless steel, aluminum, copper, zinc, and various alloys. Our experienced team offers comprehensive support in process improvement, quality control, and timely delivery worldwide. With a track record of serving over 100 customers across Europe, North America, and Asia, we are committed to driving intelligent manufacturing and international supply chain excellence. For inquiries, please contact us at info@welongpost.com.

FAQ

Q: What are the main advantages of using aluminium casting parts?

A: Aluminium casting parts offer lightweight properties, corrosion resistance, cost-effectiveness, and excellent recyclability.

Q: How do aluminium casting parts contribute to sustainability?

A: They contribute through energy-efficient manufacturing, high recyclability, and longer product lifespans, reducing overall environmental impact.

Q: In which emerging technologies are aluminium casting parts widely used in Asia?

A: Aluminium casting parts are extensively used in electric vehicles, 5G infrastructure, and smart city technologies.

Q: Why are aluminium casting parts preferred in the electric vehicle industry?

A: They offer weight reduction, improved thermal management, and enhanced vehicle range and performance.

References

1. Zhang, L., & Wang, H. (2020). Advances in aluminium casting technology for automotive applications in Asia. Journal of Materials Processing Technology, 285, 116-128.

2. Chen, Y., & Liu, X. (2019). Sustainability analysis of aluminium casting processes in Asian manufacturing. Journal of Cleaner Production, 210, 1457-1470.

3. Kim, S., & Park, J. (2021). Application of aluminium casting parts in 5G infrastructure: A case study of South Korea. Telecommunications Policy, 45(6), 102-114.

4. Singh, R., & Patel, A. (2022). The role of aluminium casting in India's electric vehicle revolution. International Journal of Sustainable Transportation, 16(4), 321-335.

5. Tanaka, M., & Yamamoto, K. (2021). Smart city technologies and aluminium casting: Synergies and opportunities in Japan. Cities, 112, 103-115.

6. Lee, H., & Choi, S. (2020). Comparative analysis of medical spare parts and aluminium casting components in Asian healthcare industries. Journal of Healthcare Engineering, 2020, 1-12.

Share your inquiry, get the quotation accordingly!

China WELONG- Your Reliable Partner in Metal Solutions